A construction fixings failure in a safety-critical installation can have potentially fatal consequences. DEWALT’s Technical Manager, Terry Hallahan, explains how to select the right adhesive anchor to ensure a safe and long lasting installation.

Adhesive, also known as chemical or resin, anchors range from high performance Pure Epoxy and Vinylesters to the popular and widely used Polyester products. Low cost and readily available, polyester anchors are all too often seen as a universal fixing solution and as such are subject to misuse. In fact, this type of chemical anchor has some serious limitations, including long term shrinkage, and is only recommended by DEWALT for non-structural or temporary fixing in dry conditions. In order to make an informed, and ultimately safe, choice we believe it’s important to understand the key differences between the various resin-bonded anchors.

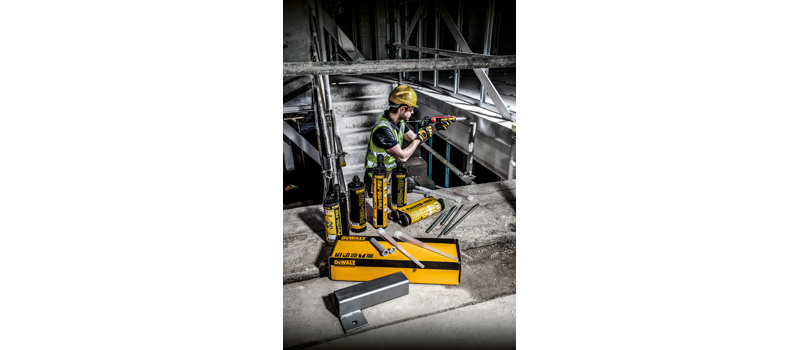

DEWALT’s recently launched range of fixing systems includes the three main types of adhesive anchor mentioned above. Each type is approved to the relevant ETA and is specifically formulated to provide a unique set of properties to suit various applications. Load capacities will depend on base material strength and integrity, stud or rebar specification and embedment depths.

To assist selection, let’s look at the different adhesive anchors in more detail:

Pure Epoxy Anchors (PURE 110-PRO and PURE 150-PRO)

These ‘premiership’ adhesive anchors offer high thermal and high loading properties with outstanding resistance to chemicals and virtually no shrinkage. DEWALT’s Pure Epoxy Anchors carry ETA-option 1 approval for use in both cracked and uncracked concrete and are suitable for diamond drilled holes. They can also be used in wet conditions/water filled holes and poor site conditions. In addition, they have the advantage of a 24-month shelf life which can be an important consideration for dealers and users.

Vinylester Anchors (AC100-PRO and AC100 NORDIC)

DEWALT Vinylester Anchors are approved to ETA-Option 1 and offer good thermal and high mechanical loading properties in a wide range of base materials. They have the advantage of fast curing times and high adhesive resistance, especially in alkaline conditions. They can be also be used with confidence in wet conditions/water filled holes.

Polyester Anchors (PV45-PRO and PV50-PRO)

With ETA-option 7 approval for M8-M24 rods, DEWALT’‘s Polyester Anchors offer a cost-effective solution for low load fixing into dry hollow blocks or masonry. Quick curing, these anchors are suited to a wide range of base materials but are not recommended by DEWALT for safety-critical applications.

DEWALT anchors and fastening systems are available through most DEWALT merchants/distribution centres. DEWALT offers technical specification support and advice for architects and design engineers, including CPD Seminars.

For more information about Anchors and Fastening Systems from DEWALT, please e-mail:

fixings@DEWALT.com or visit the website: www.dewalt.co.uk/fastenings