From the pages of PBM’s sister publication Professional Builder, Tibby Singh offers a trade professional’s perspective on Knauf’s plasterboard products and accessories.

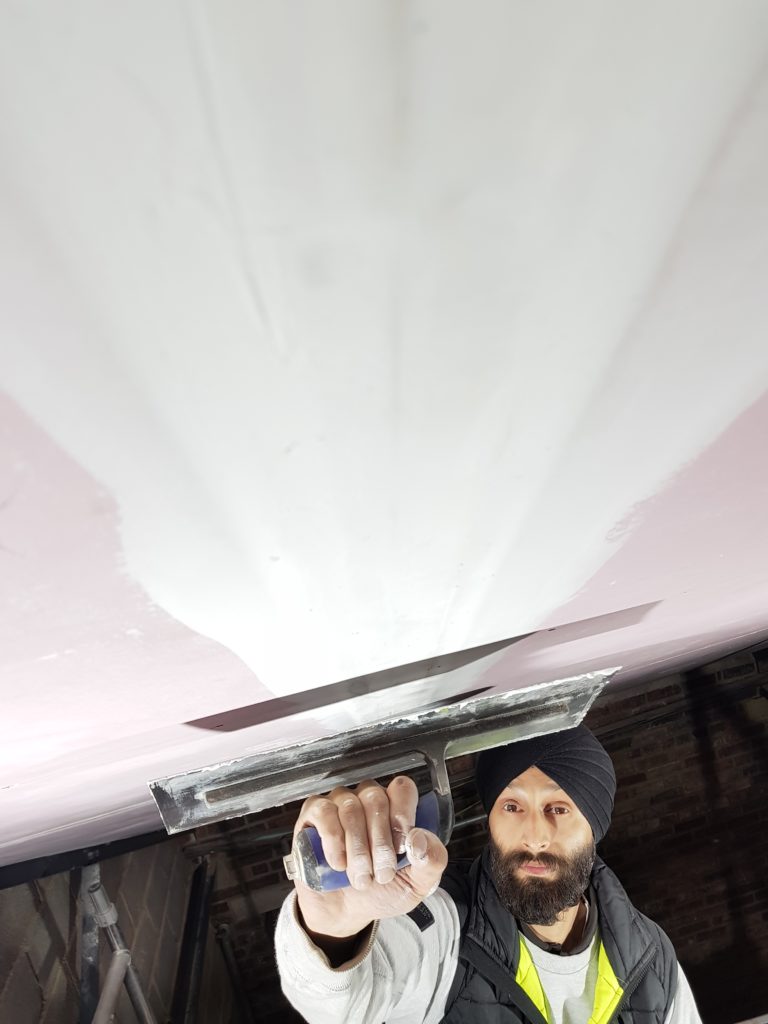

Like a lot of builders, work has been packed to the rafters recently, quite literally in the case of a plasterboarding job we’re undertaking on a 6m high pitched roof. With the height, and a huge area, the last thing that was on my mind was plastering, and that, of course, is the benefit of drylining.

I’ve been using Knauf’s Fire Panel Plasterboard Tapered Edge, with the pink colour indicating that this is a Fire Panel. Other boards are colour-coded too, with the standard board being white, sound board blue and the moisture boards green.

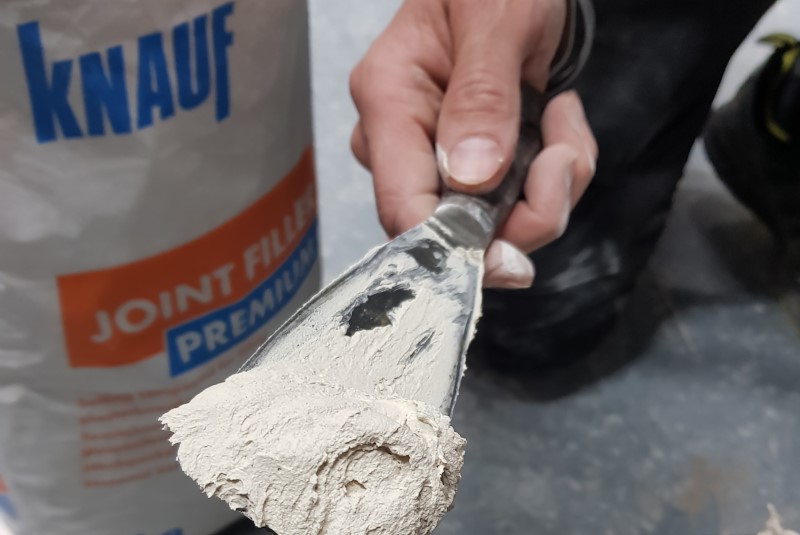

Both Knauf’s Joint Filler Premium and Joint Cement Premium are in powder form, and it’s as simple as adding water and mixing until the consistency is right. The good thing about the powder form is that you can mix the amount you need as and when you need. I don’t like to see materials go to waste, so this is ideal for me, and there’s a shelf life of nine months for the filler and 12 months for the Cement.

When filling the joint, it’s imperative that a tape is used over the joints to prevent cracking, and I used Knauf’s Paper Joint Tape. I suppose you could use a mesh tape but there are many benefits of using a paper tape. Firstly, it’s cheaper, secondly it has a crease down the middle making it ideal to use on corners and finally, if the joint is over sanded you will hardly notice the paper tape, which would be more visible with a mesh tape.

The paper tape doesn’t have a sticky back to stick it to the joint, so you would need to use Knauf’s Joint Filler Premium or Joint Cement Premium on the board before applying the tape. Although the tape is paper thin it doesn’t seem to tear very easily when running the filler knife down the joint to make sure it sits flat to the surface, which is great.

To prevent any confusion both the Joint Filler Premium and Joint Cement Premium can be used as a bedding coat. The advantage of using the Joint Filler Premium is that it sets in 90 minutes and, given that it’s a case of not just applying one coat, but two, that is very welcome. The first finishing coat of Joint Cement Premium should be approximately 10” wide; the second coat 12”, and it’s an easy and satisfying material to apply.

The Joint Cement Premium’s drying time is typically between 12 – 24 hours, but the advantage of using this one is that it enhances workability. So, even if it’s the first time you’ve picked up a spreader, you can take your time and not worry about the filler drying quickly. Another benefit is that it can be machine applied. The machine is called a bazooka which runs along the joints and it holds a substantial amount of Joint Cement. It makes sense if you’re doing large areas day in day out, and it would allow you to fill the joints from ground level, which is perfect for high ceilings. It can then be simply smoothed with a long reach spreader.

I’ve been using Knauf products for many years now and they’re very reliable, whilst the manufacturer’s System Performance Warranty is also reassuring. It’s always great to be able to rely on a company that supplies a huge range of products for different applications.

For more information on Knauf Joint Filler Premium and Joint Cement Premium, go to: https://www.knauf.co.uk/