BSW Timber

IRO Timber innovation award

IRO Timber, manufactured by BSW Timber, has claimed top spot in the Innovation category at the Wood Protection Association’s annual awards ceremony. An exclusive range of cladding and decking products which takes its inspiration from ‘Yakisugi’ — the traditional Japanese method of charring timber — IRO fought off tough competition at the prestigious awards after being shortlisted alongside Wood Campus, Gripsure and WJ Components.

IRO, which is Japanese for ‘colour’, is crafted using an intricate seven-step process that is described as “combining an eye for detail with the latest timber technology”. The award-winning product — available in a suite of 15 colours — is heat enhanced, brushed, treated, kiln dried and coated in a protective wood cream, resulting in a self-cleaning, low-maintenance surface and “adding a twist to traditional cladding and decking”.

Hamish Macleod (pictured), Director of Public affairs at BSW, said: “We are extremely proud of the popularity of IRO since its launch from both design-focused individuals and businesses alike, and it’s brilliant to see IRO being recognised for the innovative product that it is, making the team’s hard work all the more worthwhile.”

To see details on the range, go to www.irotimber.co.uk

Cheshire Mouldings

Business investment

A further £2m has been invested by Cheshire Mouldings to increase its UK production and distribution capabilities. The company says the investment will “bolster its warehouse capacity, speed up production and streamline its processes whilst continuing to provide the superior support to its merchants and stockists that it has become renowned for.”

This month, a new 30,000 sq.ft. distribution centre is scheduled to open at its Merseyside site, housing a state-of-the-art barcode picking and warehouse management system that is designed to reduce order lead times. An 80,000 sq.ft. storage warehouse will follow in late 2021. The business has also taken delivery of a brand-new automated moulding machine — a Powermat 1500 moulder from Weinig UK — to boost production efficiency.

Cheshire Mouldings also reports that its commitment to product development has seen new stair part ranges developed to mirror latest trends and styles. Common parts have been redesigned “with the tradesman in mind” to make install as easy as possible, as well as reducing stock holdings in stockists and merchants. Furthermore, the introduction of new literature, including interactive options, an updated website and improved fitting instructions across all ranges is intended to provide merchants with quick reference materials whilst also offering installers all the assistance and support they need at their fingertips.

For full details on the infrastructure investment, new product ranges and marketing support, use the link cheshiremouldings.co.uk

JB Kind

2021 Door Collection

Marking an impressive 150 years in business, Derbyshire door distributor JB Kind has announced the early launch of its 2021 Door Collection which is described as featuring “the classic styles customers love, plus some fresh new designs and twists on favourites.”

With the previous 2020 ‘iPad brochure size’ proving so popular, the 2021 collection is also being produced in the same handy format. To make life even more convenient for merchants and their customers, there is also a new online flipbook option with informative links whilst merchants will receive a QR code sticker to display so the brochure can be easily downloaded via mobile in store.

Sales Director Simon Johnson said: “We are delighted to be in a position to launch our new 2021 Door Collection early. All our top-selling favourites are still very much in situ, but we are proud of the many fresh new looks and features we are launching this year.

“We’ve come a long way since our founder John Blower Kind started out in 1870, but our ethos of great quality at affordable prices remains unchanged.”

To see more on some of the highlights of the 2021 collection — such as the Urban Industrial range and a line-up of FD30 glazed fire doors — go to https://www.jbkind.com/brochure

Medite SmartPly

Site hoarding

With merchants key customers, Medite SmartPly is outlining the importance of site hoarding as an “essential aspect” of any construction project. The firm cites the Health and Safety at Work Act 1974 which demonstrates the duty of care that all construction companies and site managers have to take all reasonable steps to ensure that both employees and the public are safe from construction work hazards, and hoarding is a crucial part of this.

Smartply Siteprotect and Site Protect Plus OSB3 panels are said to have been specially developed as solutions to the five key hoarding considerations:

- Site hoarding needs to be strong and durable enough to provide a secure barrier and withstand adverse weather.

- It should be quick and hassle-free to install, enabling projects to start on time and progress efficiently, especially in current circumstances.

- It should be adaptable to the site location.

- It should adhere to the controlled access requirements of the site and be able to incorporate appropriate signage.

- Finally, all site hoarding should always be aligned with the sustainability goals of the entire construction project itself, which can leave no room for illegally sourced tropical plywood, or boards which have unclear supply chains.

The products can be produced in structurally sound panels of up to three metres tall. These can be supplied pre-primed to ensure projects can get up and running efficiently, whilst they are also available in thicknesses of 18 and 16mm for a lighter weight — but just as durable — option where ease of install is paramount.

Finally, both versions of the FSC-certified panels have been developed to offer a smooth, flat surface to allow suitable, clearly visible signage to be incorporated easily around the site.

More details on the firm’s hoarding solutions are available via https://mdfosb.com/en/hoarding

Timber Trade Federation

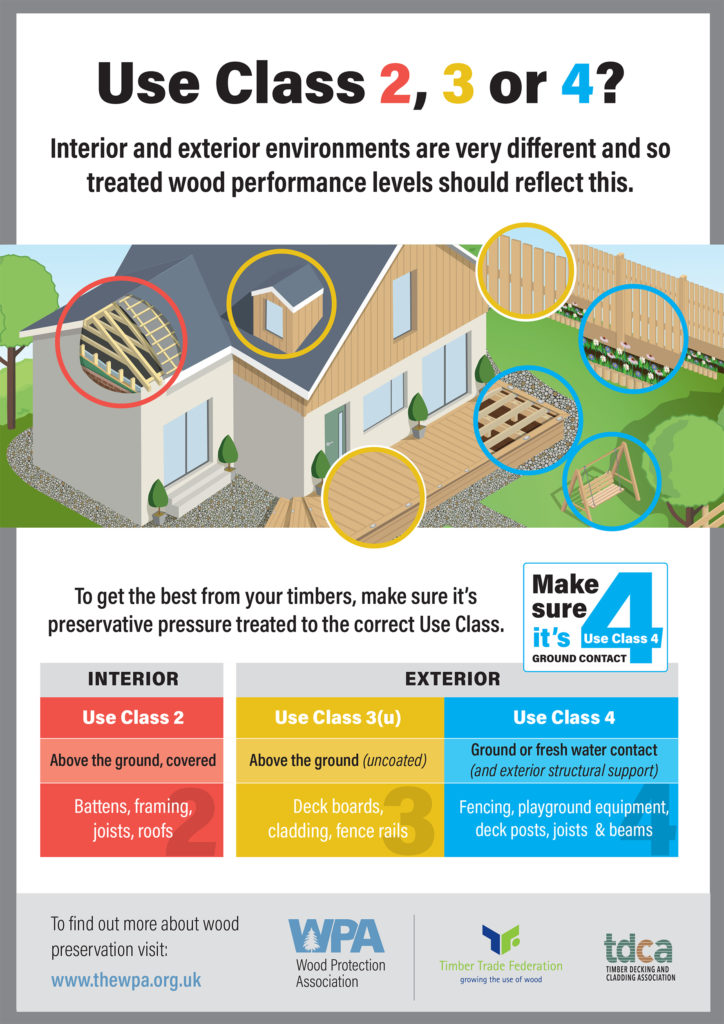

Class 4 timber treatments

Merchants are being urged to uplift staff knowledge about treated timber, particularly in relation to the regulatory change to Use Class 4 (UC4) timber treatments for any material that will be used on the ground or in ground contact, such as decking bearers. Accordingly, the TTF has been co-operating with the Wood Protection Association and Timber Decking & Cladding Association to promote this key information across the supply chain.

This is set against the findings of a survey of merchants conducted on behalf of the WPA and the TTF found that 97% did not know that a specific class of timber treatment exists for timbers used in ground contact, with only 3% recognising that a UC4 timber treatment is needed for this application.

David Hopkins, CEO of the TTF, said: “This applies not only to sleepers and fence posts but to any material sold for use underneath timber decking. Even if it is sitting on a membrane on the ground, it is still ‘in ground contact’ so must have received a UC4 treatment before being sold for this purpose.

“Educating all your staff gives merchants an opportunity to maximise sales and minimise risks.”

Joists or carcassing material is often recommended for decking supports, but this material is only treated to UC2 or UC3 for internal use within a house — its treatment is not suitable for use on the ground outside.

David added: “Timber Trade Federation members are aware of the change to UC4 timber treatment and are able to sell UC4 material to customers. Merchants need to ask their timber suppliers directly for UC4 treated timber, and ask for confirmation on the order.

Posters illustrating where different timber treatments should be used are available from the TTF for merchant’s yards and counters. Enter https://ttf.co.uk/make-sure-its-use-class-4-campaign/ for details.

Holz-Her

Vertical panel saw

Offering an efficient, on-demand sheet material cutting service to your customers could be a real advantage for merchant businesses, and Holz-Her — part of the Weinig Group — is outlining the benefits of its best-selling SECTOR 1254 vertical panel saw.

Designed and manufactured specifically for timber and builders’ merchants, the machine has been built to provide a simple, cost-effective way of cutting materials to size. Described as ‘small but mighty’, the unit has a compact footprint of just 4.085 x 1.67m to allow “even the smallest branches to benefit from the precision cutting of perfectly square panels”.

Built around a 100% rigid welded frame for strength and rigidity, the latest model in the series has a cutting length of 3,300mm (10 feet) and cutting height of 1,900mm (5’ 10”) with a cutting depth of 60mm and a standard five horse-power motor.

The saw also comes equipped with a digital display that dispenses with lengthy set-up times whilst helping to ensure accuracy and reduce waste.

For more information including a video demo, go to: https://www.holzher.co.uk/en/products/vertical-panel-saws/sector-1254.html