Preventing condensation in buildings takes a joined-up approach — and insulation is a big part of the solution. David Milner, Technical Team Lead at Celotex, considers the advice merchants can give to their customers about helping to control condensation.

Effective condensation control in buildings can be summed up as a three-pronged strategy: insulate correctly, provide adequate ventilation and manage the movement of moisture. However, the complexity of moisture management in buildings can mean that implementing these three elements is far from simple.

In particular, designers and specifiers have no control over how the eventual occupants will use a building. That means building fabric specification and detailing decisions, together with appropriate ventilation solutions, are crucial.

So, what causes condensation in buildings, and why is it a problem? Really, when we talk about condensation risk, we are really talking about two different types of condensation — surface condensation and interstitial condensation.

Surface condensation

Surface condensation refers to moisture that forms on the surface of a building element when warm, humid air comes into contact with a cooler surface. It may occur as a light dampness or, if the accumulation of moisture is large enough, it could form into droplets that run down the surface.

This process occurs when the surface cools the surrounding air below its dew point temperature, the point at which air can no longer hold all its water vapour, causing condensation to form on the surface. The dew point varies depending on the air’s temperature and relative humidity.

Window panes are the most obvious example of surface condensation occurring, because the glass is usually significantly cooler than other surfaces. If a wall or ceiling is cool enough (or the air humid enough) for condensation to occur on its surface.

Interstitial condensation

The same principles apply here to moisture-laden air coming into contact with a cooler surface. The difference is that interstitial condensation refers to the process occurring within the layers of the building fabric, rather than on exposed surfaces.

The obvious problem is that the condensation is unseen. Over time, this can wet materials within the building’s structure. Thermal insulation materials can lose performance if they become wet; timber elements can begin to decay over a period of years.

For interstitial condensation to occur there must be some failure in the vapour-closed nature of the construction, there may be a penetration of the AVCL. This allows air and moisture to pass into the construction. That air then needs to meet a cooler surface to the external side of the insulation layer.

Poor installation of insulation, which leaves gaps or voids, can also allow warm air to circulate to cold surfaces and increase the condensation risk.

How do U-values and thermal performance relate to condensation risk?

Among the measures that can be employed to control condensation are raising temperatures: either of the air, or of building element surfaces. A well-insulated building slows heat transfer, but heated air movement must also be considered. If there are pathways in the fabric that allow warm air to escape, a significant proportion of heating energy can be lost through air leakage (exfiltration) and the entry of cold air (infiltration).

Airtightness is therefore also critical, alongside an appropriate insulation specification and effective ventilation to maintain air quality and remove excess moisture.

Better-insulated building fabric with lower U-values slows the rate of heat loss and keeps surface temperatures warmer. When surfaces are warmer, humid air is less likely to cool below its dew point on contact, making surface condensation less likely.

The best insulation solutions for condensation control

Insulation that achieves lower U-values plays a key role in reducing condensation risk, beyond just meeting minimum regulations.

Thermal bridges are areas in otherwise well-insulated building fabric where the continuity of insulation (and possibly of vapour control measures too) is interrupted. Discontinuity of insulation in the building envelope can create pathways for heat loss, which lower local surface temperatures and increase the risk of condensation.

And where insulation is not continuous, these cooler surfaces can become prime spots for surface or interstitial condensation.

Getting thermal bridging right is just as important to condensation control as it is to complying with energy efficiency requirements. Little wonder then, that BS 5250:2021 Moisture management in buildings – Code of practice provides detailed guidance on the importance of junction detailing and its role in moisture management.

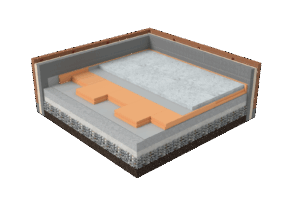

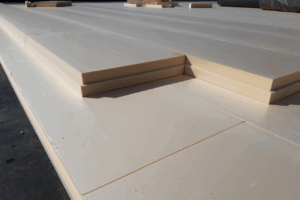

The right insulation boards

Effective insulation boards can help with thermal bridging solutions. When detailed correctly — including fixing details, service voids and vapour control measures as necessary — the right insulation boards can help to provide the continuous layers of insulation that limit the transfer of heat, reduce air leakage, and help maintain warmer internal surface temperatures.

Celotex’s range of PIR insulation boards — including GA4000 and TB4000 — can be specified for floors, walls and roofs to help achieve low U-values. Try the Celotex online U-value calculator, which includes a built-in condensation risk analysis, to accurately assess condensation risks.