Chris Cyrol, Product Marketing Manager at Epicor, considers the level of AI readiness in 2025, exploring how workforce strategy is reshaping the building supplies industry.

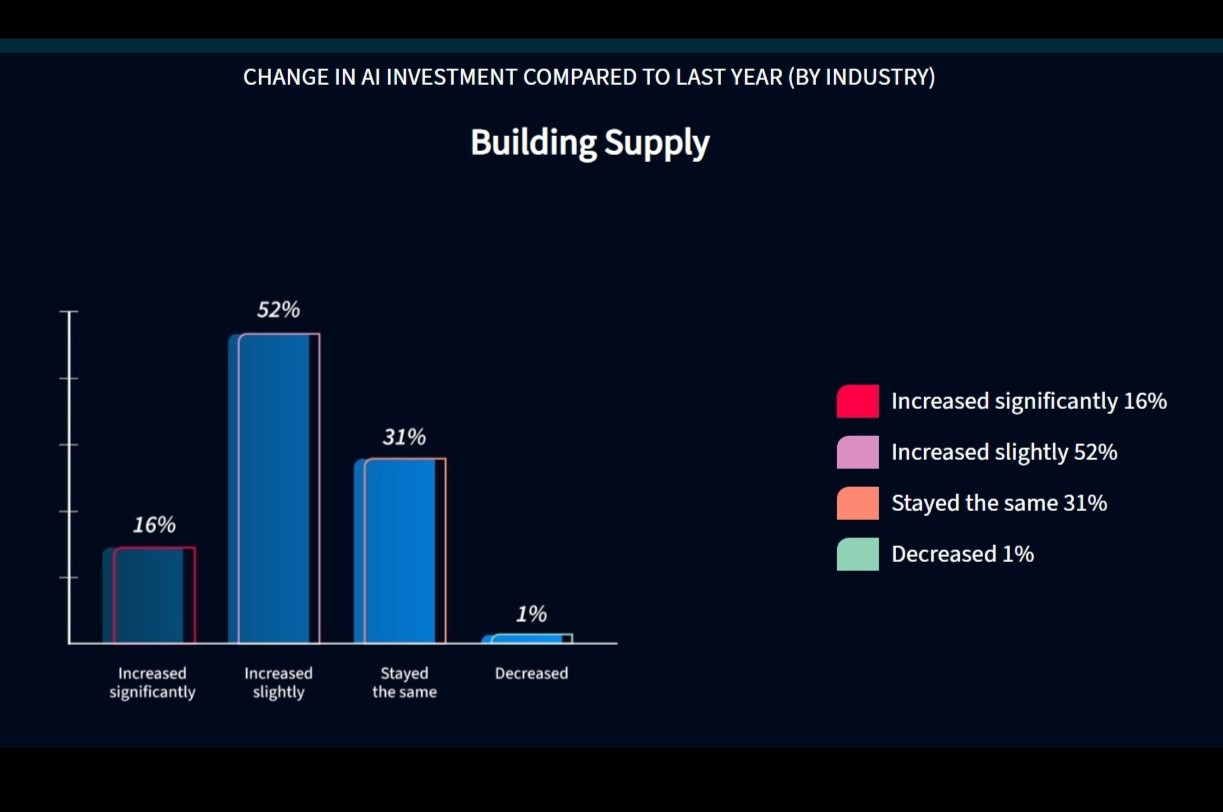

Over the past year, AI has very rapidly shifted from theory to reality for most businesses. In the world of building supplies, while AI-investment is slower compared to some industries, those investing are gaining a clear advantage over competitors.

Our latest Supply Chain Agility Index 2025, which surveyed more than 1,000 professionals across construction, manufacturing, distribution and retail, shows a consistent pattern. The companies most prepared for AI are the ones investing in their people as much as their platforms.

Across the building supplies industry, AI is starting to make a quiet but noticeable impact. AI is supporting merchants with planning by forecasting what’s needed, managing inventory and keeping deliveries moving. The real difference, though, comes from the people using it: the staff on the ground who know the trade and can turn data into smart, practical decisions.

People drive AI success

There’s still some concern that AI might replace people, but the evidence points in the other direction. Businesses making progress with AI are expanding teams rather than shrinking them.

New roles such as AI logistics and route optimisation specialists, AI-powered demand planners, and automation engineers are beginning to become part of everyday operations. These professionals are using technology to plan delivery routes and anticipate supply bottlenecks, managing materials with greater accuracy.

“AI is starting to make a quiet but noticeable impact, supporting merchants with planning by forecasting what’s needed, managing inventory and keeping deliveries moving.”

Many builders’ merchants are already experimenting with AI. Some systems now predict demand for seasonal stock — insulation, cement, aggregates and landscaping materials — so branches can prepare well before busy periods hit. Others are using smart routing tools that tweak delivery schedules as traffic builds or site timings change, cutting wasted journeys and fuel costs.

A few have gone further by linking sales data directly to warehouse systems so best-selling products like timber lengths or fixings are topped up automatically rather than waiting for manual checks.

AI is also changing how merchants interact with customers. On trade websites and ordering platforms, AI-powered virtual assistants can now answer quick questions about stock, specifications or delivery times, while predictive tools flag alternative products when certain materials are unavailable.

In branch, this means counter staff spend less time checking systems and more time giving practical advice. It is still people who make the difference — AI simply helps them work with fewer delays and a clearer view of what’s happening across the yard.

The new trifecta: talent, technology, and infrastructure

Businesses embracing AI are taking a more holistic approach to supply chain transformation. The ones seeing real results are rethinking how their teams use information and how decisions flow through the operation.

Across the building supplies industry, technology is being used to model supply and demand in real-time, giving merchants early visibility of potential problems such as delayed deliveries or low stock on high-demand items. Procurement teams are using predictive analytics to stay ahead of price changes in core materials, while AI-powered warehouse tools are improving accuracy and speeding up fulfilment, cutting errors and keeping projects on schedule.

With skilled people and advanced technology working in tandem, suppliers are building stronger, more resilient operations. But how can leaders build AI maturity into their business?

How to build AI maturity

The Supply Chain Agility Index 2025 outlines a clear roadmap for those looking to accelerate AI adoption into 2026. The first step? Hire AI expertise early to build capability before scaling up tools or platforms.

Next comes a digital audit to identify weak points in data systems and workflows.

Once those are addressed, businesses should pilot AI in high-impact areas such as demand planning, inventory control, or route optimisation.

Companies following this step-by-step approach are seeing tangible results within 6-18 months, from faster delivery times and reduced waste to smoother supply chain operations.

For merchants and manufacturers, the message is clear: AI should be integrated into everyday operations rather than treated as a standalone project. Taking the time to create a workforce strategy that combines human capability with technology is becoming the real differentiator.

As fluctuating material prices, labour shortages and unpredictable demand continue to test industries, the businesses that align leadership buy-in with talent development and data infrastructure will be best placed to lead.

Click here for more information on Epicor, and to download its Supply Chain Agility Index 2025.