What has been billed as “the UK’s first drive-thru station for concrete, mortar and screed” is set to debut soon at an independent builders’ merchant in north Wales. PBM reports.

Set open in February, Thorncliffe Building Supplies is launching “the UK’s first fully automated, self-service batching plant” for concrete, mortar and screed at its Ewloe branch. The local builders’ merchant’s customers will be able to collect “exactly the right amount, exactly when they need it at the push of a button” with orders from as little as 0.25m3.

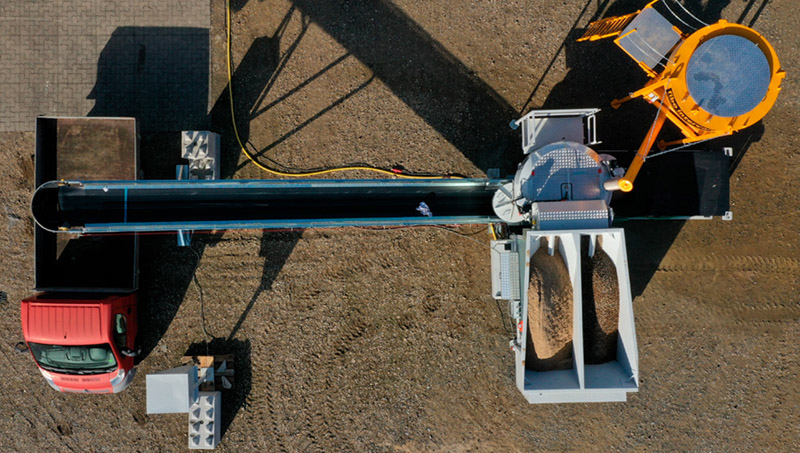

The new drive through collection station — known as a ‘Fibo Collect’ machine, manufactured by Danish concrete solutions supplier Fibo Intercon — has been engineered to help save people in the local community both time and money whilst also having a positive impact on the environment.

The concept works by offering a solution to the current challenges facing smaller builders, landscapers and local DIYers who need only small to medium loads of concrete, mortar or screed. Typically, they will currently receive it via one of three ways:

By mixing on site themselves, which can be an expensive and often time-consuming route;

Collection from a local ready-mix plant, which can bring about problems with waiting times and issues when special mixes are required;

Delivered to site by volumetric trucks — this is said to be by far the most popular route but customers are often subject to minimum order charges, issues with waste disposal and problems with waiting times.

With an international track record, Fibo Collect was initially launched to the UK market in late 2022. Henrik Jeppessen, Fibo Intercon CEO, said: “When we looked at the UK, we saw a huge opportunity to tackle the customer challenge posed by concrete delivery. Our solution ultimately gives (a merchant’s) customer more choice: choose exactly what type of recipes, how much you want to collect, when you want to collect and even how you want to pay.”

Thorncliffe Building Supplies was amongst the very first to see show an interest, with the company’s Adam Harper commenting: “We are delighted to introduce this new technology to our customers as we think it will be a game changer in 2023. When we saw the machine in action, we immediately thought about our local customers and the many benefits they could gain from having the collect service.”

Thorncliffe Building Supplies was amongst the very first to see show an interest, with the company’s Adam Harper commenting: “We are delighted to introduce this new technology to our customers as we think it will be a game changer in 2023. When we saw the machine in action, we immediately thought about our local customers and the many benefits they could gain from having the collect service.”

The fully-automated mini batching plant will allow customers to access the collection service by following a simple four-step method in the branch:

Order at the till;

Collect your barcode;

Position your vehicle or tub under the conveyor belt;

Scan the barcode at the touchscreen terminal on the machine to start mixing.

As indicated above, customers can receive their concrete, mortar or screed directly onto the back of a trailer or flatbed truck. Alternatively, they can dispense the product into a mortar tub which can be loaded onto a truck or van at the branch.

And whilst larger loads can vary, for a small load of concrete under 0.8m3 the entire mixing and pouring process is said to be complete in under five minutes.

For the merchant’s trade or DIY customers, there are said to be a number of benefits in addition to the convenience and time-saving the service offers. For instance, the dynamic mix options include various concrete, mortar or screed recipes whilst the automated mixing technology with its “cutting edge” control panel is said to ensure that “all recipes are high quality and consistent.”

Additive control further enables the user to control the workability and setting time of the material, whilst the solution is also billed as being environmentally friendly, releasing less carbon omissions through being “less wasteful than traditional bulk concrete mixing methods.”

For the merchant, Fibo Intercon says the batching plants will allow stockists to develop additional revenue streams, helping to grow market share and attract new customers. Equating the self-service aspect to being “just like filling up at a petrol station,” it adds that many merchants are already buying sand, aggregate and cement in large quantities but “are missing an opportunity.”

It says that: “The difference in the margin to make concrete and to buy corporate ready-mix is about 25% (and) this difference allows builders’ merchants to take market share from the corporate ready-mix companies and make an additional margin.”

The supplier says the quality of its machines matches that “of any ready-mix plant and conforms to BS 8500, EN 206,” whilst its batching plants can produce up to between 10 to 40 m³ of high-quality concrete per hour, storing up to 60 concrete mixes and can change from one concrete mix to another “with the click of a button.”

Click or tap the links for more information on Fibo Collect and to see a brief video explainer of the concept.