Laying claim to being the only UK manufacturer of both concrete and steel lintels alongside a host of other structural building solutions, Stressline celebrated its diamond anniversary last year with its commitment to providing merchants with the “best quality service, product mix and price” key to its ongoing success. PBM spoke with Managing Director Chris Fox and Commercial Manager Marc Coulson to discover more about the company’s growth, discussing its latest product developments and support services for merchants.

Founded in 1964 by Keith Fox and Bob Mullard, Stressline’s evolution has been fuelled by innovation. In 1968, for instance, the business pioneered high volume pre-stressed concrete lintel production whilst 1970 saw the creation of the first hybrid steel and concrete lintel. With the in-house expertise to develop the systems and processes that allowed the business to “quickly move from small scale to large production,” further advances rapidly followed, reflecting the changing needs of the market.

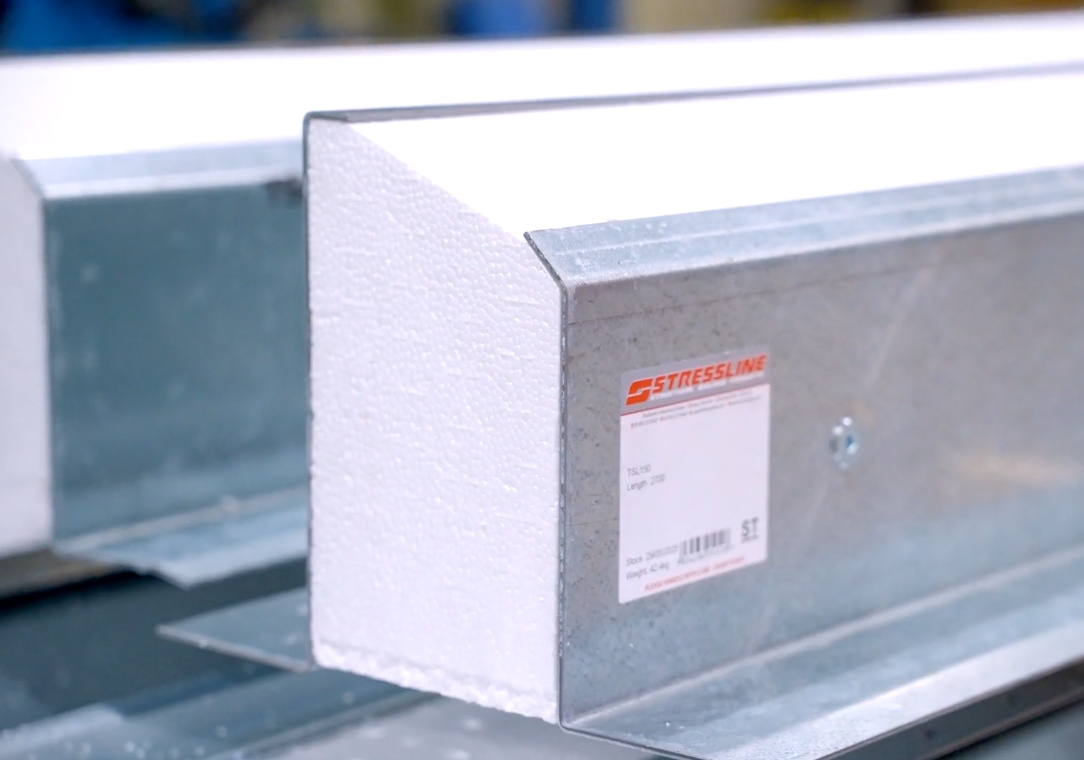

Whilst its heritage was built on the concrete products that remain a central part of its operations today, the business was one of the earliest pioneers of thermally broken steel lintels in 1989, and a focus on new product development continues to the present day with the recent launch of the Thermo+ range — billed as a ‘truly uncompromised’ solution to combatting heat loss that is “up to five times more thermally efficient than a standard lintel” (see panel below) — as the necessity to improve energy efficiency grows ever more important.

Building on the foundations of its core products, innovations along the way have even included solutions as diverse as wall panels for the agriculture industry to terracing systems for sports stadia — from the likes of Chelsea and Leicester Tigers to the smaller grounds of Northwich Victoria and Stalybridge Celtic — and ‘curved’ sections for achieving the optimum view in cinemas!

Bob Mullard retired in 1985, whilst Keith Fox passed the business over to his sons in 1997. Current MD Chris Fox then acquired the firm from his brothers in 2015 and, from its substantial 26-acre site on the outskirts of the Leicestershire village of Stoney Stanton, the growing product portfolio extends beyond its twin concrete and steel lintel offering to include an array of flooring, walling, fencing and precast section solutions.

“We’ve been able to navigate the challenges (faced by) the merchant industry to continue to offer what they need in terms of price, quality and service.”

Family-owned foundations

The family-owned legacy and history of innovation is cited as a vital point of difference for the firm, which Chris says helps it to “punch above our weight.” The business, he says, is nimble enough to “identify emerging opportunities” and can “quickly bring new products to market” meaning that “we’ve been able to navigate the challenges (faced by) the merchant industry to continue to offer what they need in terms of price, quality and service.”

Accordingly, serving merchants is described as “the thrust of our business.” An active member of both BMF and NMBS — with the supplier’s stress-busting massage chair a legendary feature of its presence at the NMBS Exhibition each year — Stressline works with the major industry buying groups and builders’ merchants nationwide (with independents comprising its largest customer component).

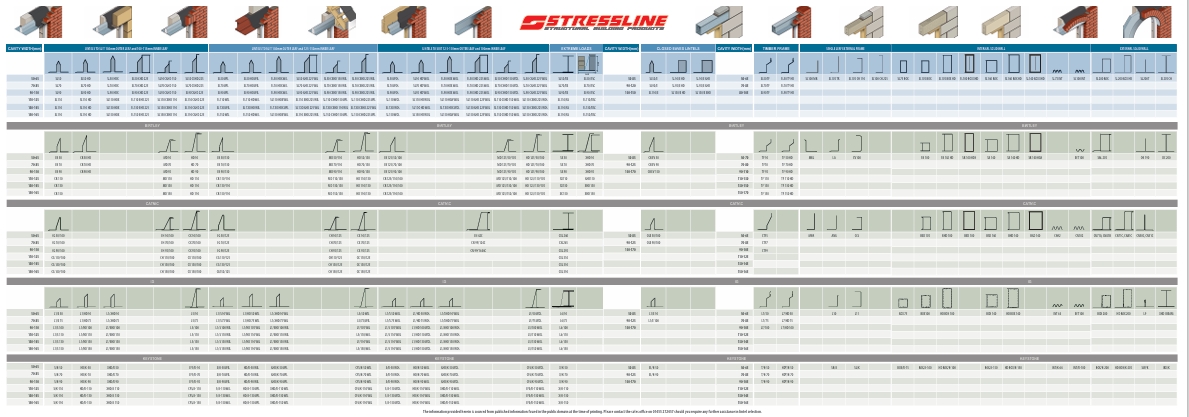

Full marketing and point of sale — from brochures and technical literature, including unique comparison charts, to sample boxes and banners — is available whilst the business is committed to supporting the sector through live events and trade days at merchant depots.

With a dedicated team out on the road, backed by internal sales alongside comprehensive design and technical support for specials and bespoke products, Stressline also reaches out to developers, architects and specifiers with orders processed via the merchant channel.

Commercial Manager Marc Coulson is front and centre in the drive to develop and enhance the supplier’s presence in the merchant market. He comments: “We’re a small team, but we’ve worked well at building and creating partnerships within the industry and with our merchant customers.”

Mixed loads

With substantial stockholding at its Leicestershire base, priority is placed on ensuring efficient deliveries across its full portfolio. Standard products can be supplied nationwide, typically within three to eight working days, whilst the advantages of offering both concrete and steel lintels, for example, mean that mixed product consignments can help minimise delivery costs and ensure maximum efficiency for customers.

The supplier offers full design and technical support with the capacity to produce custom / bespoke designs and quotations for projects of all sizes, all back sold through the merchant channel. The technical and scheduling department provides expert advice for merchants, developers, architects and specifiers, using the most up to date standards for assessing loads and ensuring that its lintels — whether they need to be steel, concrete or a combination of both — are suitable for the job.

As its literature states: “Our promise is simple — to deliver competitively priced products, on time, to the required specification.”

Since taking on the business fully around the time of the company’s milestone 50th anniversary in 2015, Chris explains that “the marketplace has changed dramatically” whilst the ongoing uncertainty and economic challenges continue to present obstacles for the industry as a whole. However, just as with its stress-busting massages offered at the NMBS show, he is keen to point out that Stressline is there to offer support and reassurance to its customers.

He concludes: “What has made us unique as a manufacturer and supplier over many years is the mix of product that we still carry today — and especially offering both concrete lintels and steel lintels. We can go into a merchant and say, ‘our range is broader and far more comprehensive than anything you can get from anybody else’ and with our experience, especially as an independent ourselves, we can take a different approach: we listen to our customers and we try to act.”

Click here for more information on Stressline and to download copies of its latest product guides.

Stressline Thermo+

Improving thermal performance in buildings is more important than ever, and reducing thermal bridging is key to achieving better energy efficiency. Stressline’s Thermo+ steel lintels have been developed to help minimise energy waste, helping to make builds more sustainable and compliant with the updated Part L Building Regulations.

Key features include:

Thermally efficient design: Offering a cost-effective way to lower carbon emissions.

No base plates, clips or brackets: Less material conducting heat = reduced thermal bridging.

Decreased psi value: Indicating a lower heat loss through the lintels, thereby improving the overall thermal performance of the wall and the building as a whole.

Two-part lintel system: Separate lintels for the inner and outer leaf of the wall, effectively creating a break in the thermal bridge between them to significantly reduces heat transfer compared to traditional lintels.

Stressline: core product range & service offering

Concrete Lintels: Prestressed for strength and durability, suitable for supporting masonry, timber floors, roof loads, and more. Available in standard, high-strength and fair-faced finishes.

Steel Lintels: Galvanised and designed for cavity walls, solid walls and timber frames. They offer a wide range of duty ratings — from standard to extra heavy duty — with built-in plaster keys and thermal efficiency options.

Flooring Systems & Precast Sections: Includes beam and block flooring, padstones, windposts and other precast components.

Technical Support, CPD and Scheduling: Stressline provides load span tables, CAD designs and RIBA-approved CPD materials for specifiers. Lintel schedules can be produced directly from architectural drawings (plans, elevations, sections, etc) with custom solutions available for unique project requirements.

Nationwide delivery and strong merchant partnerships: Mixed load consignments to boost efficiency.

Compliance with British & European Standards: Products are designed and tested to BS EN 845-2, BS EN 846-9, and BS 5977-1, among others.