New figures produced by Tobermore reinforce what the company describes as its “continuous commitment to minimising environmental impact” whilst also improving service efficiencies for merchants. PBM reports.

Between 2020 and 2021, Tobermore reported a 15% increase in loads delivered across the UK and Ireland, whilst simultaneously increasing the percentage of full load (single delivery) deliveries “by a staggering 25%”. In the same time period, the number of deliveries made on multi-delivery loads decreased by 20%.

The manufacturer firmly places these successes with its Transport Team, which has doubled its resource in the past year and is responsible for ensuring environmentally focused delivery planning. Furthermore, “significant factory investment” has also enabled the company to ramp up production and capacity to meet the surge in demand for its paving and walling products, thus reducing lead times and maximising full lorry loads.

Additionally, Tobermore notes that its commitment to reducing its environmental footprint can also be seen in its approach to sustainable packaging design. Last year, the company overhauled its product packaging, which now consists of 100% recyclable polyethylene film containing 30% recycled material. By using recycled material, Tobermore has decreased waste and reduced its packaging-related carbon footprint by 20%.

These environmental benefits are said to come “with no downfall to the quality or efficiency of their packaging; the impressive strength and durability of the original film will be maintained”.

This year, the company says it was the first to market in publishing Environmental Product Declarations (EPDs) for all its paving, walling, and kerb products. Following a “rigorous Life Cycle Assessment (LCA)”, Tobermore can now “accurately demonstrate the environmental impact” of over 400 products, enabling construction professionals to compare different products and make informed decisions about which to choose for their project from a sustainability perspective.

MD David Henderson said: “We have made a massive commitment to take our environmental responsibility very seriously. A joined-up effort between our Transport Team and our Haulage Partners has ensured that, with calculated route planning and maximising loads, we can reduce our carbon footprint.”

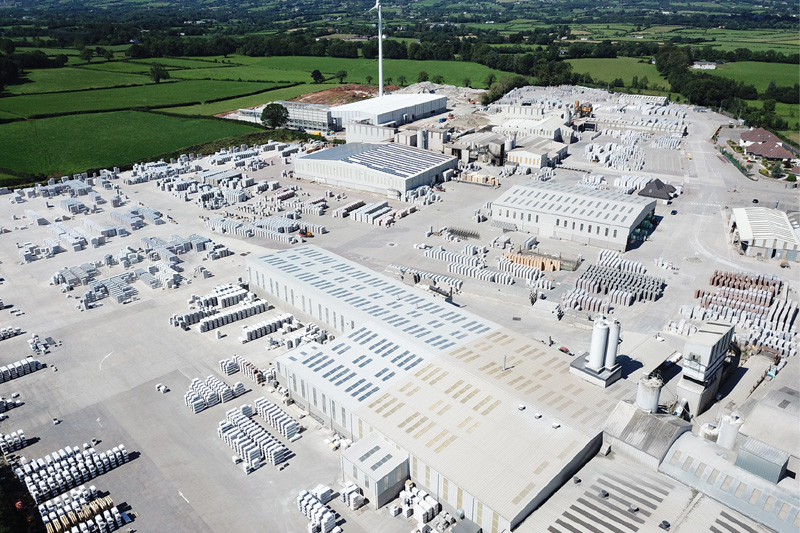

As alluded to previously, the company has also announced the opening of its new £8.6 million production facility which will enable it to further scale up production to meet the demand for its products.

The facility, which officially opened in June, boasts an industry-renowned SR Schindler Press — only the second of its kind to be operational globally — plus a Shotblaster and state-of-art packaging line. Allowing for the increased production of high-demand products including Braemar, Mayfair, Beaufort, Textured, Riven, and Classica Flags, the investment will ensure Tobermore can continue to meet the growing demand for its products whilst “ensuring all its paving flags are in stock with zero lead times”.

Rigorous pre-launch machine testing was carried out by engineers from across the globe including from Germany, Slovakia, and Poland who were also involved in the machinery setup. Involvement from Northern Ireland companies, including Rapid and PIL, was also imperative to achieving the highest standard of operations.

Tobermore has grown significantly in recent years — increasing its workforce by 54.3% from 302 employees in May 2020 to currently employing over 460 staff across the UK and Ireland — with the latest factory following the opening in December 2020 of a £10m, 4416m² facility featuring a HESS block paving machine. This enabled the expanding company to ramp up production by an additional 30% and generated 95 new jobs locally.

Commenting on the latest factory opening, David Henderson said: “Tobermore proudly reinvests in areas of the business that satisfy customer demand. We are delighted our latest production facility will generate additional job opportunities in our local area, as well as enable us to meet the growing demand for our paving flags. Boasting world-class machinery installed and tested by a team of expert engineers, we are passionate about producing outstanding products without the lead times.”

Click the link for more information on Tobermore’s product range, its sustainability commitments and merchant support services.