Taking a wider perspective on the broader UK manufacturing sector, Shane Taylor, Manufacturing Sales Manager at ECI Software Solutions, explores why AI, data and people power will define the year ahead.

Persistent cost pressures, intensifying global competition and ongoing trade complexity are testing even the most resilient businesses. At the same time, new technologies, a renewed push for industrial strategy and the drive toward net zero are creating powerful opportunities for those able to harness them.

This tension between challenge and momentum has put manufacturing on the brink of major transformation. Leaders across the sector know that standing still is no longer an option. The businesses that embrace modern technology, strengthen their data foundations and empower their people will be the ones to regain competitiveness and secure long-term growth.

AI becomes the competitive edge

AI is already influencing how many UK factories operate, but adoption remains fragmented. According to Make UK, around 70% of manufacturers are investing in digital tools, yet only 10% run fully digitalised operations, and robot density in the UK still sits at about half the EU average. The result? A sector where AI is present, but not yet fully harnessed.

“When production, stock, sales and scheduling data lives in one place and updates in real time, teams can make quicker, more confident decisions. Issues surface earlier, duplicated efforts disappear and resources can be planned with greater precision.”

In 2026, progress will be driven by manufacturers applying AI in more deliberate, operationally grounded ways. Rather than focusing on isolated pilot projects, firms will increasingly use AI to stabilise production schedules, uncover inefficiencies earlier and create smoother links between planning, supply chain and the shop floor. These are the areas where AI can deliver immediate value without major disruption.

For many, the aim will be simple: shift from experimenting to embedding. The manufacturers which see the greatest gains will be those who integrate AI into everyday decisions, using it to strengthen reliability, reduce friction and close the digitalisation gap that has held back the sector in the UK.

Data the new driver of performance

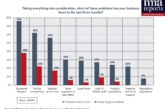

While AI attracts the headlines, it’s the strength and clarity of a manufacturer’s data that will dictate how far these tools can go because AI can only work at its best when the information behind it is accurate and connected. Make UK reports that only 54% of manufacturers use ERP or MRP systems to manage supply chains, leaving almost half reliant on ageing systems or spreadsheets to run fundamental processes. That limits accuracy, slows decisions and makes it harder to maintain consistent performance.

The priority now is consolidation. When production, stock, sales and scheduling data lives in one place and updates in real time, teams can make quicker, more confident decisions. Issues surface earlier, duplicated efforts disappear and resources can be planned with greater precision.

This shift doesn’t require cutting edge automation. Reliable insight into defects, cycle times, downtime or demand patterns is enough to materially strengthen output and stability. It’s the manufacturers that invest in these data foundations that will find it easier to handle volatility, improve efficiency and adopt new technologies at their own pace.

Resilient, tech-enabled supply chains

The UK’s global supply chain links show just how exposed manufacturers are to disruption. Around half of UK output depends on the sourcing and sale of intermediate inputs, with manufacturing in particular relying heavily on complex international networks. A significant share of this exposure is indirect — routed through partners in Europe, the US and elsewhere — which means many vulnerabilities sit several tiers back in the chain, out of immediate sight.

In 2026, the response should be less about pulling back from global supply chains and more about managing this complexity with greater intent. Manufacturers should put more focus on identifying where critical inputs really come from, mapping dependencies beyond preferred suppliers and using planning tools to test “what if?” scenarios around delays, tariffs or demand shifts.

When this is combined with clearer operational data and closer coordination between supply chain, finance and production, it becomes possible to move away from constant firefighting and towards more deliberate, resilient and profitable supply chain strategies.

Empowered people, smarter work

Despite fears about automation replacing jobs, the reality across the sector is far more nuanced. Manufacturers remain clear that people are their most valuable asset but the skills landscape is tightening, and the work is becoming more complex.

In 2026, we’ll see greater emphasis on human–AI collaboration, using automation to remove repetitive tasks so skilled employees can focus on problem-solving, continuous improvement and higher-value activities. As digital tools become more accessible, they will act less as replacements and more as extensions of capability.

This shift will also support recruitment and retention. Manufacturers that offer modern tools, clearer data and less manual admin give employees the environment they need to work effectively, develop expertise and stay engaged.

To reinforce this point, Make UK highlights that the year ahead will demand a sharper focus on practical technology adoption and the skills required to use it. As Nina Gryf, the organisation’s Senior Policy Manager, explains: “Manufacturers are clear about what they need in 2026: practical support to adopt the right technologies such as ERP, AI or robotics, a better understanding of how these tools can be applied on the factory floor, and a stronger grasp of the data they can leverage across their business.

“Just as importantly, they need support to train their workforce, so people have the skills to use these technologies confidently and effectively. The companies that get this right won’t just improve productivity — they’ll strengthen their competitiveness at home and abroad. With the right backing, UK manufacturing can turn digital transformation into real advantages and move into the year ahead with confidence.”

A more confident future

The outlook for 2026 is not defined by disruption, but by opportunity. Manufacturers don’t need to transform everything at once to move forward, they need to focus on the foundations that unlock reliable performance: stronger data, practical automation, clearer visibility and tools that help teams make informed decisions.

Those that take a steady, structured approach through investing in what works, not what’s fashionable, will be better equipped to compete globally, withstand volatility and move with greater confidence into the decade ahead.

Click or tap the link for more information on ECI Software Solutions’ services for merchants.