Peter Drakeley, Head of Customer Success at EazyStock, discusses the importance of effective inventory management and how it can improve competitiveness and profitability.

Anyone who sells products will tell you that stock availability is a critical factor to success. With customers working to tight deadlines, more and more are demanding same or next day delivery. At the same time, merchants are expanding their sales channels to offer online ordering, adding a new layer of transparency across the industry.

Merchants who want to grow their business and maintain profitability have a lot to think about. Many are focused on enhancing their online user experience or investing in solutions to manage omni- channel sales and pricing. Others are modernising their back-office systems, such as their enterprise resource planning (ERP) platforms, to increase operational efficiency.

Fewer, however, are looking at ways to ensure they have the right products in stock to meet customer demand. This strategic approach is known as ‘inventory optimisation’, and it’s being embraced across a range of industries, from automotive and energy, to retail and electrical wholesale.

What is inventory optimisation?

Inventory optimisation is a relatively new concept and can often be confused with basic inventory management processes. Whilst inventory management includes ordering, managing and tracking stock, inventory optimisation is the art of balancing high service levels with the lowest possible inventory investment.

It allows businesses to ensure product availability, while reducing inventory costs and minimising excess stock. This is done by forecasting demand and managing supply variables, whilst dynamically adjusting stock rules and inventory parameters. The objective of inventory optimisation is to have the right products, in the right place at the right time — as efficiently and cost-effectively as possible.

Whilst most ERP platforms provide basic inventory management functionality, inventory optimisation plug-in tools can easily be integrated with these systems to offer a more comprehensive solution. But even without the software, basic inventory optimisation principles can still be practiced and focus on three critical inventory management functions:

- Demand forecasting

- Stocking policies

- Replenishment

Accurate statistical demand forecasting

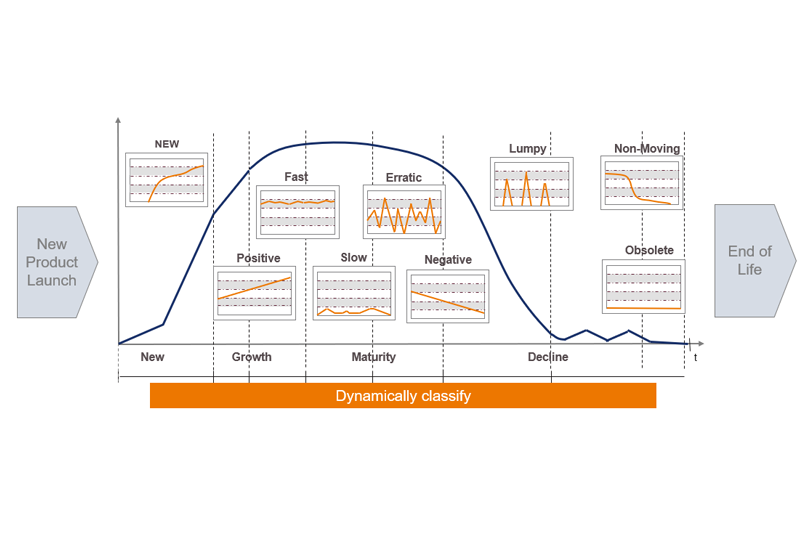

Traditionally, demand forecasting methodology has used a moving average calculation (historical average demand over x months) to predict future demand. However, this simple equation has many drawbacks. Most notable is that it fails to take into account an item’s product lifecycle.

As a product moves from growth to maturity and decline, its demand patterns will also change. For example, a product that’s in its growth stage could have a high level of consistent demand, whereas one reaching decline could have low, erratic demand as sales drop off. Demand types are important as each has a different deviation from its mean average demand, and this impacts the type of statistical algorithm that should be used to forecast demand.

Inventory optimisation techniques take demand types into account. By working out a product’s current position in its lifecycle and its consequential demand type, the most appropriate algorithm is used to produce the most accurate forecast. In addition, this more advanced approach to demand forecasting identifies demand variables — such as seasonality, trends and promotions — and adds these to the forecast, improving its accuracy.

Optimised stocking policies

Many businesses make the mistake of thinking that they need to carry excessive amounts of inventory to ensure product availability. In reality this simply ties up large amounts of working capital and warehouse space, and increases the risk of excess and obsolete stock. In contrast, inventory optimisation utilises inventory classification and stocking policies to achieve high fulfilment rates with the lowest possible stock levels and, therefore, investment.

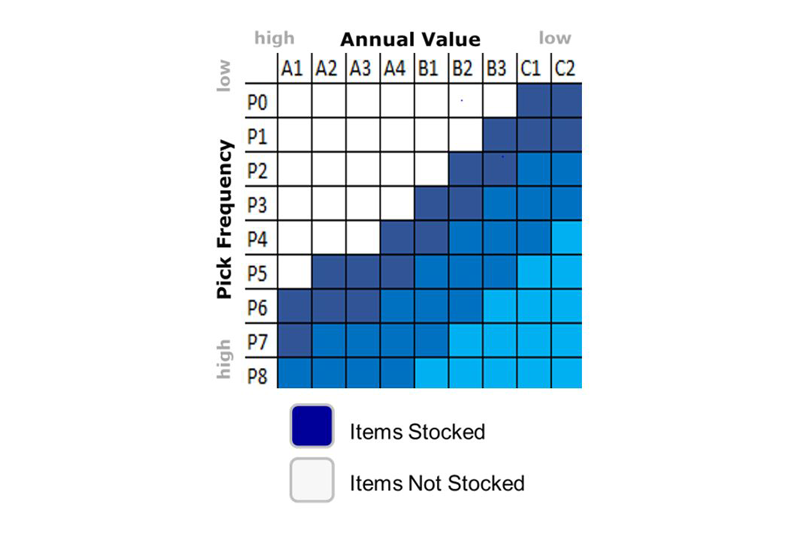

This is done by analysing stock at SKU level and grouping items based on a number of criteria. Firstly, it makes sense to increase the stock of products that are picked frequently than those that sit on the shelves. Secondly, based on demand volatility, it is less risky to stock products which have consistently high demand than those where demand fluctuates up and down. And finally based on the value that a product brings to the business — for example, this could be its sales revenue, profitability, sales volume or annual consumption value.

With every SKU categorised into an inventory matrix, businesses can then set strategic stocking policies about their stock levels, helping to avoid carrying excess stock whilst still ensuring demand can be met.

“Whilst inventory management includes ordering, managing and tracking stock, inventory optimisation is the art of balancing high service levels with the lowest possible inventory investment.”

Cost-effective replenishment

The final stage of inventory optimisation is calculating how much stock to reorder and when to reorder it, so demand can be met as cost-effectively as possible. Unlike basic replenishment calculations that use linear, one dimensional formula, inventory optimisation algorithms take into account supply and demand variables.

For example, most businesses will reorder either when they hit a fixed date or when stock drops to a specified level. The amount they reorder is usually either a fixed amount or variable to meet a minimum or maximum stock capacity. Many ERP and WMS systems will use one of these approaches.

A more dynamic approach, however, is to factor in demand forecasts (so ordering meets customer demand), supplier lead times (taking account of supplier constraints) and cost-effective order quantities (weighing up the cost of carrying and opportunity costs against cheap bulk buys).

Inventory optimisation brings business-wide benefits, for example:

Product availability and reputation: Preventing out-of-stock scenarios removes the risk of lost sales and unhappy customers. Inventory optimisation policies can maintain service levels of up to 99% with minimised inventory, leading to higher customer loyalty, a stronger brand and more sales.

Lower stock levels: Inventory optimisation practices lead to a reduction in stock levels, releasing important working capital that can be used elsewhere in a business. Plus, a higher stock turnover rate will free up valuable warehouse space.

Removes the risk of obsolete stock: With stock levels consistently optimised to match forecasted demand and with a close eye on every product’s position in its product lifecycle, the risk of excess and obsolete stock is dramatically reduced.

Better supplier management: By factoring supplier lead times into replenishment rules, businesses instantly reduce the risk of stockouts. Order quantities and reorder points will take into account supplier lead times and safety stock can be increased to cover risky periods.

Cost-effective ordering: Knowing whether it’s more cost-effective to order small quantities frequently or larger quantities less often can bring notable cost savings over time. Determining order frequencies and quantities to take account of demand and supply variables allows businesses to reduce inventory but still achieve service levels.

EazyStock is actively looking to engage with the merchant sector and recently joined the BMF as a Service Member. For more information visit www.eazystock.co.uk