With press-fitting fast becoming the go-to solution for installers, John Gittens, Business Development Director of Maincor, looks at why merchants should be taking stock of its advantages too.

While traditional fitting methods still have their place, press-fitting systems are making their presence felt among an increasing amount of installers, not least because of the time that can be saved on site. And though it is not possible to please all your customers all of the time with one single product, and some will undoubtedly always prefer to stick to tried and tested materials and methods such as soldering copper, merchants ignoring the rise in popularity of press-fitting do so at their peril.

Press-fittings can make the completion of a job up to three times faster than with conventional methods and significantly reduce the amount of time that needs to be spent on site. With no site assessments and hot works permits needed, installers can simply get on with the job. In fact, the absence of a naked flame makes the fitting process a whole lot safer too — and particularly suitable for retro-fit projects, which is another good reason for the rise in popularity of press-fitting.

Safety first

Undoubtedly though, the biggest selling point of press-fitting — and the one that merchants should be highlighting to customers who may be wavering between making the switch or not — is the peace of mind it offers installers that the end result is safe, correctly sealed and free of leaks. This is something that cannot always be said of traditional or push-fit connecting methods as with traditional methods, there is a risk that the fitting could be left incomplete if the installer cannot get the solder to flow correctly around the joint, resulting in leaks which can be both difficult to detect and costly to fix.

Press-fitting systems, such as those from Maincor, overcome this issue and offer less opportunity for errors to occur, as the fitting will leak if not pressed correctly or adequately. The system’s one large O-ring is also much more substantial than an ordinary O-ring, as it is much harder to dislodge or damage as the pipe goes into the fitting, smoothly and quickly.

Other benefits of this option include a larger internal bore which allows for significantly increased flow and viewing windows that allow the installer to check the pipe is inserted correctly, reducing the chance of joint assembly errors occurring.

The right fit

A versatile choice, Maincor metal press fittings can be used to create permanent non-demountable systems from sizes 16-63mm, with a patented ‘D’ ring construction for a secure plumbing connection.

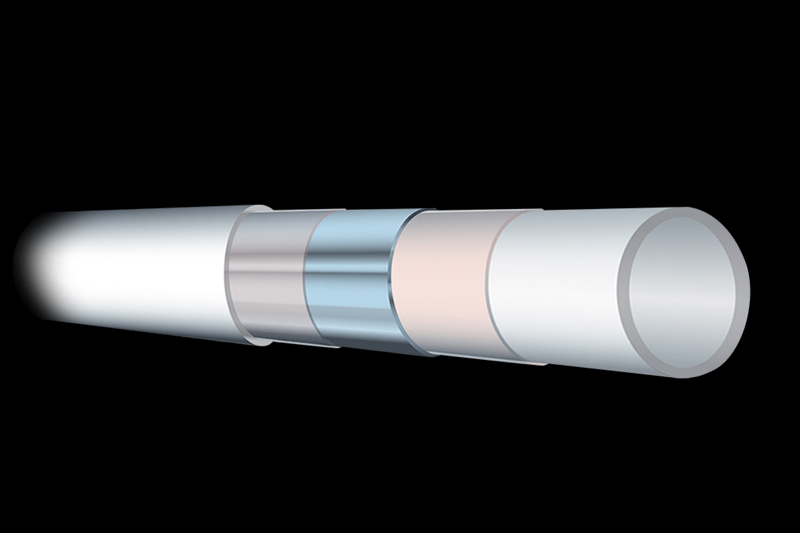

Metal is not the only material of choice when it comes to press-fittings though. Maincor Impress composite press fittings, for example, offer a simple and cost-effective method of jointing MLCP in both domestic and commercial projects.

Suitable for both hot and cold water plumbing systems and heating applications and made from polyphenylsulfone (PPSU), the body of the fittings offers exceptional stability and a toughness superior to other high-temperature engineering resins. This resin also offers a high deflection temperature and resistance to environmental stress cracking, with the polymers being flame retardant and thermally stable.

“The biggest selling point of press-fitting — and the one that merchants should be highlighting to customers who may be wavering between making the switch or not — is the peace of mind it offers installers that the end result is safe, correctly sealed and free of leaks.”

Multiple connections

When a ‘go to’ connector is needed, Maincor’s Multi-fit range is about as versatile as they come. A simple and effective way of connecting Maincor MLCP to potable plumbing systems, heating, underfloor heating, kitchen and bathroom appliances, Multi-Fit connectors are simple to install, with no special tools required. In fact, all that is needed are pipe cutters, a bevelling tool and an allen key.

The pipe is cut to length and bevelled at the end, the fitting is inserted into the pipe, before the allen key is used to screw the thread into place. Once the pipe is fully visible in the viewing window, the connection is made. Multi-Fit connectors are available in a wide range of sizes with ½”, ¾” and 1” compression nut connections, and come with both an O-ring for conical seats and a flat washer for flat face applications.

By brushing up on the systems and fittings available, as well as the benefits of each depending on the application, merchants can help customers make an informed choice while cashing in on what is now an established pipework connection method.

For more information on Maincor’s range of products and services, go to https://www.maincor.co.uk/plumbing/