With an ongoing drive to maximise the energy efficiency of both new and existing properties alike, Tony Armitt, Commercial & Technical Director at ForgeFix, discusses the importance of educating customers on the changing insulation regulations and the solutions which can ensure compliance.

For the past couple of decades, the UK government has introduced various schemes and initiatives to make both new homes and older houses more energy efficient. The likes of the Green Homes Scheme, The Great British Insulation Scheme (GBIS) and Energy Company Obligation have encouraged homeowners and landlords to work on making homes more energy efficient.

Similarly, when it comes to new builds, the Future Homes and Buildings Standard, introduced in 2021, has laid out new regulations that mean new build homes built from 2025 must produce 75-80% less carbon emissions. With this in mind, builders and contractors have to make sure that they have the correct and best quality materials for the job.

Approved Document L

The government recently introduced new building regulations to reduce the amount of wasted energy in homes. As part of these regulations, insulation thickness has increased to reduce the U-Value of homes.

A U-Value measures how well parts of a building transfers heat and is a measure of heat loss in the building in areas such as a wall, roof or floor. In layman’s terms, the lower the U-Value, the better insulated the home.

The new regulations have had their biggest impact in loft and roofing insulation. Loft insulation is now required to be 270mm for example, whilst floor insulation should be 150mm, pitched roofs 170mm and, between rafters, 100mm board insulation is needed. Flat roofs should be 150mm and this can be laid over the deck or 100mm over the deck and 50mm between the roof joists.

These changes have had a significant impact in the designs of rooms as well as the materials needed to construct them.

“If shorter screws are used with thick insulation, they may not reach the framing behind, reducing the stability of the insulation and potentially causing it to sag over time.”

Furthermore, due to this increase in thickness, the materials that are used to secure the insulation have also needed to adapt. For example, to secure 150mm insulation onto a timber deck board with an 18mm timber overlay board, a tradesperson would require a screw at least 220mm long to produce a firm fixing.

With this in mind, it is essential to know which materials, fixtures and fastenings should be recommended to customers to use for the job.

Extended screws

It’s important to note and advise that certain screws are needed for the thicker insulation because they provide a more secure grip and help to penetrate the full depth of the insulation, ensuring that it is properly supported. If shorter screws are used with thick insulation, they may not reach the framing behind, reducing the stability of the insulation and potentially causing it to sag over time.

Additionally, using longer screws can prevent damage to the insulation, as it helps to distribute pressure more evenly.

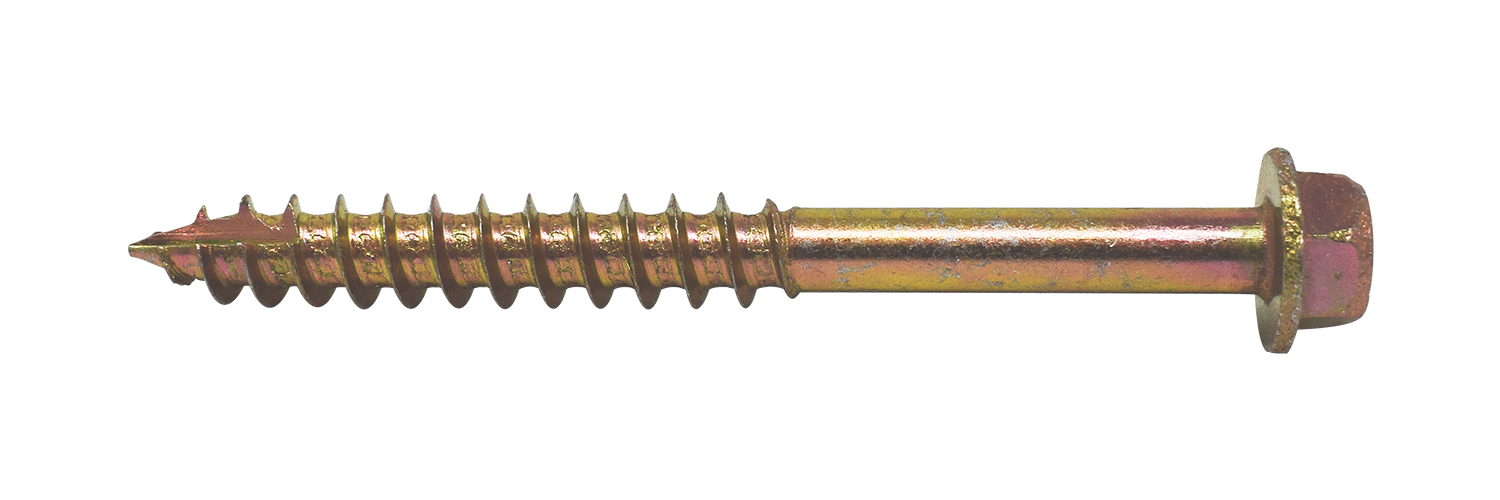

A great product to recommend is ForgeFix’s newly expanded Spectre woodscrew range. The advanced multi-purpose portfolio added new sizes of screw to help the trade comply with the building regulations and now includes 6.0 x 200mm and 6.0 x 240mm woodscrews as well as 8.0 x 180, 200, 240 and 280mm versions. The range is specifically designed to make the tradesperson’s life just that little bit easier. To support tradespeople, the size of the product is conveniently included on the packaging so the right screw for the job can be easily found.

The range is specifically designed to make the tradesperson’s life just that little bit easier. To support tradespeople, the size of the product is conveniently included on the packaging so the right screw for the job can be easily found.

What’s more, ForgeFix also provide longer screws in the TechFast range which is also used for more technical timber roof insulation installations and the range is self-screwing — once again making the job easier for the tradesperson.

The TechFast range also offers screws in sizes 5.5 x 185mm and 5.5 x 235mm — these are specially designed to fix roofing panels to a steel frame whilst providing a waterproof fixing. The longer lengths are sufficient to pass through the insulation and the screw is designed to self-drill into the metal frame up to 12.5mm thick.

Only 10mm of visible thread is required, making 185mm screws suitable for most applications. What’s more, the Techfast screws come with a hex head for increased torque, have an EPDM rubber/stainless steel washer and have an exterior coating which is C4 rated according to standard ISO 12944-2.

Having the right fixings and fasteners to hand not only make the job easier for tradespeople but also give customers assurance that the job’s been well done.

Visit forgefix.co.uk for more information on the Spectre, TechFast and ForgeFix ranges, along with information on the company’s support services for merchants.