Chris Turner, Operations Director at John A Stephens, speaks to PBM about the vision behind the merchant’s journey to becoming a CLC Construct ZERO Business Champion.

One of the largest independent builders’ merchants in the Midlands and operating from two branches in Nottingham, John A Stephens has been established more than 50 years and prides itself on delivering great customer service with same/next day deliveries utilising one of the largest dedicated HGV delivery fleets in the industry.

As far back as 2010, the business was proactive in seeking to reduce its Carbon Footprint and installed 100kW of Solar PV cells on a section of warehouse roof on its main yard site. However, then Managing Director Peter Stephens’ vision was to go much further and he commissioned plans to expand the Solar generation capability by a factor of three — enabling the entire site to be at least 80% powered by self-generated, 100% renewable energy.

This would help support the transition from diesel powered yard vehicles to a 100% EV yard fleet, with the ultimate aim of becoming the first independent merchant to achieve Construct ZERO Business Champion Status from the Construction Leadership Council.

Operations Director Chris Turner explained: “The brief was clear. Peter and his son Andy (the current MD) wanted a minimum of 300kW of solar PV generated power, feeding an entirely new 500kW on-site energy distribution grid, providing power for up to 40 electrically powered yard vehicles.

“On top of this not insignificant challenge, they also wanted the entire yard-lighting replaced with High Output Low Voltage floodlighting to improve employee safety and enhance the customer experience during the winter months.”

Turning vision into reality had a considerable number of challenges to overcome. Working closely with specialist solar energy system contract partners EVO Energy, Chris and his team had to collaborate closely with the DNO, Western Power Distribution (WPD) to upgrade the existing 80kW mains incomer to the site to a completely new set up capable of distributing over 500kW around an 8 acre site.

“The reduction in the company’s environmental impact is compelling, with a forecast 1.2m kg reduction in CO2 emissions over 25 years. Similarly, with an estimated energy cost saving of £1.7m over the same period, the scheme makes sound financial sense as well.”

With a sense of understatement, Chris said: “This meant the installation of an entirely new substation and 1.5MW transformer as well as over 500m of armoured HV cable, going under a main access road and new underground cable tunnels all over the site, all to be accomplished without any interruption to trading!”

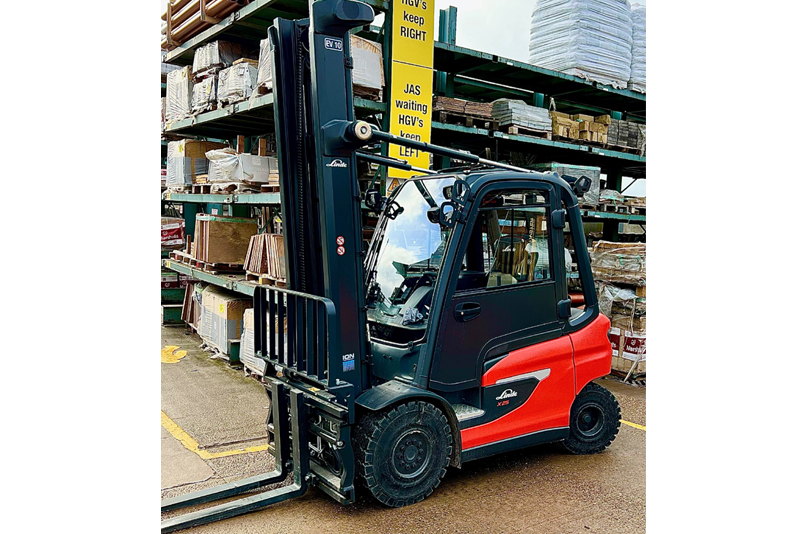

Completion of the project was accomplished in just under 12 months from the placement of initial orders, through to the installation and commissioning of the Solar panels power grid and the delivery of the first EV forklift trucks. Germany’s Linde Materials Handling were chosen as the provider of EV trucks using its brand new X Series industrial counter-balanced trucks in 2.5 and 3.0 ton variants.

Chris continued: “We chose Linde as our truck partner as we had been impressed with the quality and robustness of its H series diesel trucks and its excellent service response, so although we did evaluate several other manufacturers EV truck offerings, it felt like the natural choice to come back to Linde. The team at Linde Jewsbury’s in Castleford really bought into the project and have provided us with excellent support throughout the purchase and delivery phase.”

The investment in the 28 new trucks and rapid-chargers alone accounted for c. £1.4m of the overall £2m scheme cost.

With the 300kW Solar PV system commissioned and in operation at the end of June 2022 (see main image), John A Stephens was able to take full advantage of the unusually hot and bright weather that we enjoyed over summer 2022, allowing export generation levels to exceed imported electricity by a factor of more than four.

An export agreement with Renewable Energy distributor Good Energy has allowed the Company to achieve a high export price for the first year of export generation which has significantly reduced the forecast ROI of the solar PV element of the project from nine years to three.

And the reduction in the company’s environmental impact is compelling, with a forecast 1.2m kg reduction in CO2 emissions over 25 years. Similarly, with an estimated energy cost saving of £1.7m over the same period, Chris says the scheme makes sound financial sense as well.

“We have significantly reduced the carbon footprint of the business, however for us this is really just the first phase of our longer-term strategy.”

The company’s alignment with Priority 1 of the CLC’s Construct ZERO Performance Framework was achieved with the arrival of the Linde X –Series Lithium ION battery powered EV trucks, and similarly powered specialist Combi-Lift EV4000 side loaders. This allowed 98% of diesel plant to be eliminated from the Yard Operations by the end of December 2022.

Looking to the future, John A Stephens’s ambitions continue to be focused on further reducing its carbon footprint. Chris revealed: “In most conditions, we can now self-generate over 80% of our own power and in optimised conditions we can export almost five times more pure renewable energy than our house load requirements.

“We have significantly reduced the carbon footprint of the business, however for us this is really just the first phase of our longer-term strategy.”

The merchant is now working with key OEM suppliers on the next phases of decarbonising its delivery fleet — for example, it is trialling 100% electric EV HGVs and utilising the new Ford e-Transit for Zero-emissions local deliveries, particularly for customers in residential areas. The company is also collaborating with French OEM Manitou, aiming be the first to introduce PHEV Hybrid truck mounted forklift delivery vehicles in 2023.

In terms of ongoing development of the site, the business is now looking at the potential introduction of a new Battery Storage Scheme to complete the self-generation cycle. Chris said: “We’ve run out of roof-space, so we now need to find an effective way of harnessing our export power and feeding it back into the site energy grid to create a closed loop system.”