Under its Korniche brand, Made for Trade has already enjoyed considerable success with its award-winning roof lanterns and has latterly set its sights on the bi-fold door sector. Terry Smith, editor of PBM’s sister publication Professional Builder, reports back from its expanded production facilities in the north east of England.

Professional Builder’s very first and legendary product tester, the late Charles Godfrey certainly knew a good thing when he saw it, but even he would have been amazed at the incredible rise to fame of Stockton-on-Tees-based Made for Trade. Our annual award for innovation, which bears Charles’s name was presented to the company in 2018 for a new type of aluminium roof lantern which was already creating some seismic shock waves throughout the industry.

The ‘Korniche’ represented a real breakthrough moment in the entrepreneurial career of Richard Gaunt, whose association with the window industry goes back more than forty years. As he enthusiastically explained to us at the time: “Great design features and precision engineering enable the Korniche to be fitted in minutes and glazed in seconds — with no silicone sealant required in the body of the lantern.

“This is possible because the manufacturing tolerances are so tight that it fits together snuggly, so water can’t get in, and by any slim chance it does the internal drainage comes into play and guides it to the outside. In addition to that, the aesthetics are pleasing to the eye and we can offer a wide range of sizes to suit all budgets, so all in all the Korniche lantern has really disrupted the market and set new standards.”

What no-one knew then of course was that disruption on a scale not experienced in living memory was just around the corner. Yet paradoxically, the impact of Covid 19 on businesses like Made for Trade which caters exclusively for the home improvement market and where there was unprecedented demand for more living space, has been overwhelmingly positive.

And just how successful the company has been in expanding its market share and reputation soon became apparent when, with restrictions finally receding, we were invited to visit its impressive new headquarters a few miles north of Middlesbrough.

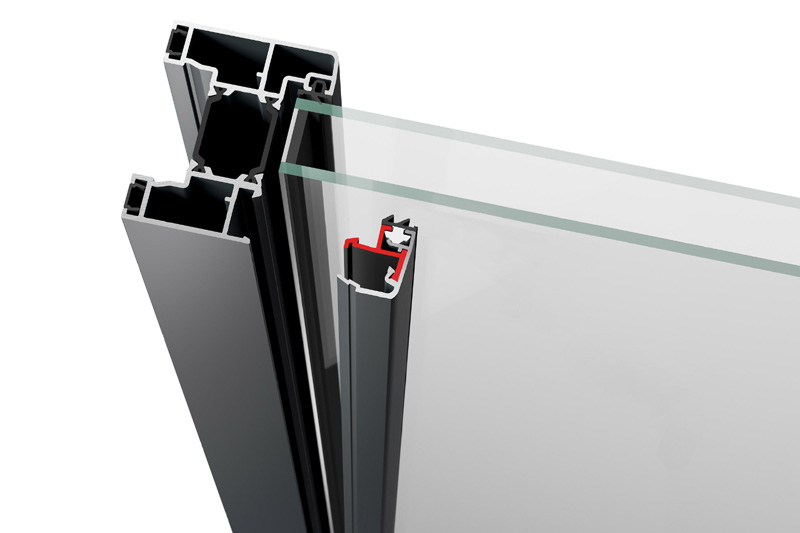

One of three fabrication sites located in the north east of England, occupying more than 250,000 square feet and employing in excess of 250 operatives, the Wynyard site is home to the company’s latest innovation — the Korniche bi-folding door. Created as a “completely new system from the ground up”, the engineering team, of which Richard’s sons Bradley and Ashley now play a pivotal role, builds on the company’s long-standing reputation for precision, simplicity, and “refined aesthetics” for the consumer.

This sits alongside benefits for the installer which, thanks to high manufacturing tolerances, eliminates the need for a wedge gasket, reducing the beading time for the fitter to a matter of seconds per sash. At the same time, a special deglazing tool is supplied with each kit that engages down the glass line to remove beads quickly, enabling glass to be removed without risk of damage to the powder coating finish.

All-important security is provided by a clever new shoot bolt handle with an anti-back drive element. Build options allow sashes up to 1.25m, systems up to 6.5m width and 2.5m height between one and seven sashes, with a range of weatherproof finishes.

Meanwhile, at the recently opened Hartlepool factory, the company is also offering a sliding patio door under the Visoglide Plus brand, either for commercial entrances or as a dynamic residential patio door. All main sections feature an extended polyamide thermal break that allows the sliding door to achieve first clast thermal properties when installed with an appropriate sealed unit.

Ian Bousfield, MFT Marketing Manager, explained: “The growth experienced by the company during the past six years has been exceptional by any standards, but the groundwork was clearly put in place during the many years leading up to that point. All that business acumen and experience, together with a wholehearted commitment to investment in the right machinery and people saw the launch of the Korniche roof lantern in 2016, and its unprecedented success has given the company the confidence and belief to disrupt the established markets with new and innovative products like our new bi fold doors.

He continued: “There is no doubt that one of the consequences of the pandemic has been the greater demand for more space within a property for day to day living and, of course, working from home. Projects appear plentiful right now for those builders who specialise in extensions and conversions, and as a business we are totally committed to providing them and their customers with the sort of products which can further enhance those projects. It’s been an incredibly challenging but ultimately highly rewarding period in the company’s long history, and you can sure we won’t be resting on our laurels any time soon. Watch this space!”

Click here for further information on the Korniche bi-folding doors and roof lanterns from Made for Trade.

Despite historically operating largely through a distinct and separate supply chain, the builders’ merchant sector has increasingly seen the potential in recent years of selling doors, windows and related products to its existing trade customers. Many merchants and suppliers have worked to navigate the incumbent difficulties of stocking and supplying such typically large, often fragile and precisely-specified products through the use of effective marketing support and IT-based solutions to open up a viable and valuable sales route.

Made for Trade, for example, offers prospective partners dedicated merchant product account support in addition to an “instant online trade counter quote and ordering tool”. In-branch POS, marketing and sales support is available, whilst the company’s made to order products are offered with free direct to site delivery.