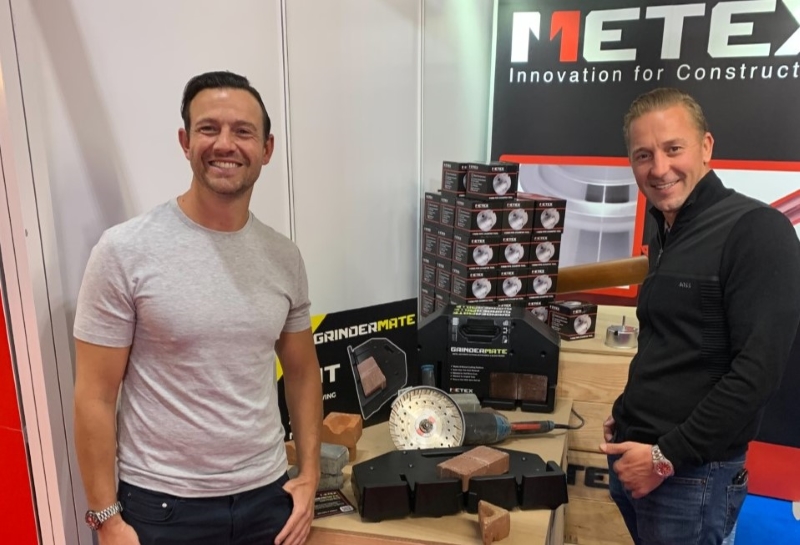

Recently launched to market by Metex, the creators of Grindermate — Mark Thompson and Jim Wigan — spoke with PBM about the creation and development of the lightweight cutting jig for bricks and block paving.

As angle grinders and rotating saws are some of the most dangerous tools in construction, having a simple jig to avoid having to hold a brick in place with a foot and running a rotating blade right next to it seems like a no-brainer. And with 20 years of industry experience apiece, Grindermate’s creators Mark Thompson (quantity surveyor and director) and Jim Wigan (who ran his own building company) got the idea because of safety concerns on a big paving job back in 2016.

Jim explains: “We were doing a very big driveway job with a labourer who wasn’t very skilled, so it was more to do with keeping him safe — he had an accident and nearly severed his toes! We were doing thousands of cuts, so I made a prototype wooden jig for him to use, just something so I could go to work and not worry about the labourers in the background — Grindermate sort of created itself from there on!”

Jim kept using the jig with his staff for another three years, until he sat down with Mark to take it further. As a commercial director of a construction company, Mark was drawn to the health & safety aspect: “For every company I’ve worked for, health & safety has been everything. I saw Grindermate and thought ‘Why are people not using this, it’s so easy and effective?’

“It baffles me how people would put their foot on a brick and cut it with an angle grinder, it’s pretty dangerous and scary! It just seemed so simple, so we decided to team up.”

Product development

The initial Grindermate was a simple wooden platform which Jim built himself, with a single straight slot in the middle, but he soon needed to upgrade the jig. He said: “We ran into a problem doing angled cuts as the brick wouldn’t stop moving around, so I developed it a bit more so we could cut angles on it.”

To make Grindermate into a viable product which could be manufactured cost-effectively as one piece, Mark and Jim started working with a plastic manufacturing company which gave feedback on the strength of materials to use and the design evolved.

Field testing with a plastic prototype saw further design tweaks, for example to increase stability, and the next stage was to take the product to market and finding a ‘middleman’ to help sell to the large companies. Mark’s industry connections led them to Metex and a meeting with its directors Daniel Bamford and Daniel Hopkins.

Mark said: “They were really keen. The business was small enough for the product to be important to them, but at the same time big enough to make it happen, so that’s why we chose them to come along on this journey with us!”

Jim and Metex then combined their skillsets to finalise Grindermate’s design. Following further tweaks and trials, Daniel Bamford said: “The reaction from contractors and builders’ merchants has been very positive and we are pleased to be promoting a product that has genuine site safety benefits.”

Changing attitudes

Seasoned tradespeople are sometimes set in their ways and getting them to adopt new tools can be a challenge, but Jim isn’t daunted: “One thing they can’t avoid is the fact that it’s safer. I’m having work done at my house now and my labourers have been using Grindermate daily — you couldn’t take it off them now! Once you get it into their hands and they try it out, I think they can be won over.

“As a boss, you’ve also got an obligation to provide PPE to your staff, like steel toecap boots for example. The legal responsibility comes back to the owner if a staff member has an accident, so a lot of bosses on construction sites will hopefully encourage their staff to use Grindermate.”

Jim additionally thinks busy builders are likely to appreciate Grindermate as a quick, ready-made solution: “As a builder you just want to get in and get out. It’s much easier and faster to just grab Grindermate, rather than waste time which could be spent building and making money. Builders want to build quickly and they like new tools — when a new tool comes out, all my boys talk about it!”

And compared to heavy brick jigs available from tool manufacturers, Grindermate is aimed at builders on the move — being smaller, more portable and more affordable. Mark explains: “Some jigs are £200-300 apiece and they’re heavy and lumpy, take up a lot of space and need a lot of setting up. We’re in a completely different market to them and try to make things simple and cost-effective instead.”

Future outlook

With Grindermate beginning to be taken on by several stockists and resellers, the two pioneers say they have plenty of ideas to take the concept further, with additional features such as dust suppression and developing a version for using up on a roof to cut tiles.

Daniel Hopkins, Metex Sales & Marketing Director, concludes: “With so many injuries on site per year, Grindermate provides significant health and safety benefits and whilst it’s got to be commercially viable for Metex, we’re really happy to help make sites safer.

“The product is priced to be highly competitive but equally very robust and provide the user a tool that will assist with hundreds of on-site brick and block cuts if treated correctly. It’s set to become a staple tool in many builder’s vans and available from most well-known merchants and online construction material retailers.”

Visit metexonline.com/grindermate for more information and for details on how to become a stockist. Alternatively, contact 0800 130 3646 or sales@metexonline.com

A version of this article appeared in the September edition of Professional Builders Merchant. Read the full issue in digital format via the PBM website.