Well-established in the bulk cement market, Hope has now officially unveiled its new bagged products which, for the first time, are all available in the company’s own packaging.

Available immediately, the launch includes 12 key products which the company says are designed to “freshen up the sector and create real value for stockists”. Underpinned by a customer-centric approach and strong brand heritage, Hope’s customers can expect to benefit from advanced packaging technology and unparalleled delivery service, which aims to provide a consistent lead time commitment of 1-3 days.

Hope says it will also be launching a sector-leading incentive scheme for builders’ merchants and professional builders, bringing a new approach to the market driving traffic into their stockists and helping to grow their businesses.

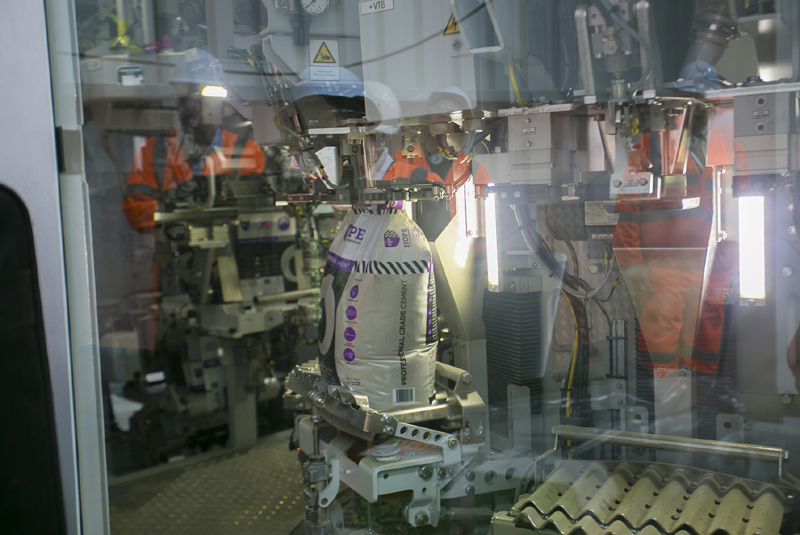

The new flagship product is the Professional Grade Cement, whilst full product range is packed exclusively in durable plastic packaging. This not only weatherproofs the products, but also ensures better durability in transit and storage, in turn increasing the overall product shelf life and improving inventory management options for stockists.

The cement is produced at the Hope Works in Derbyshire, which has been making cement for more than 80 years and is described as being the UK’s largest cement works. The Professional Grade Cement can be produced from a single source of limestone and, as a result, it offers “incomparable consistency and a lighter mortar to suit a variety of applications”.

Hope’s customers can expect to benefit from advanced packaging technology and unparalleled delivery service, which aims to provide a consistent lead time commitment of 1-3 days.

Hope’s Commercial Director, Gary Brennand, said: “The chances are that professional builders have already been using Hope cement as we’ve been supplying it to merchants for years through a third party supplier. However, this launch follows 18 months of research and development, which has seen us interview thousands of builders’ merchants and professional builders to understand what really matters to them. As a customer driven business, we’ve incorporated this valuable feedback into our value proposition and believe we have created a truly unique offering.”

All of Hope’s cement is transported from Hope Works by tailor-made rail wagons to the company’s new £14 million depot in East London. The purpose-built facility, which sits on the former Ford motorcar site in Dagenham, benefits from pioneering packing technology, which delivers 1,300 bags every hour and 60 bags per pallet. Almost all of the air is extracted from the bag, which ensures a very neat stack and load stability; this is enhanced by the use of a shrink hood system, which also provides additional weatherproofing properties.

For further information visit www.hopecement.com or follow @Hope_InABag