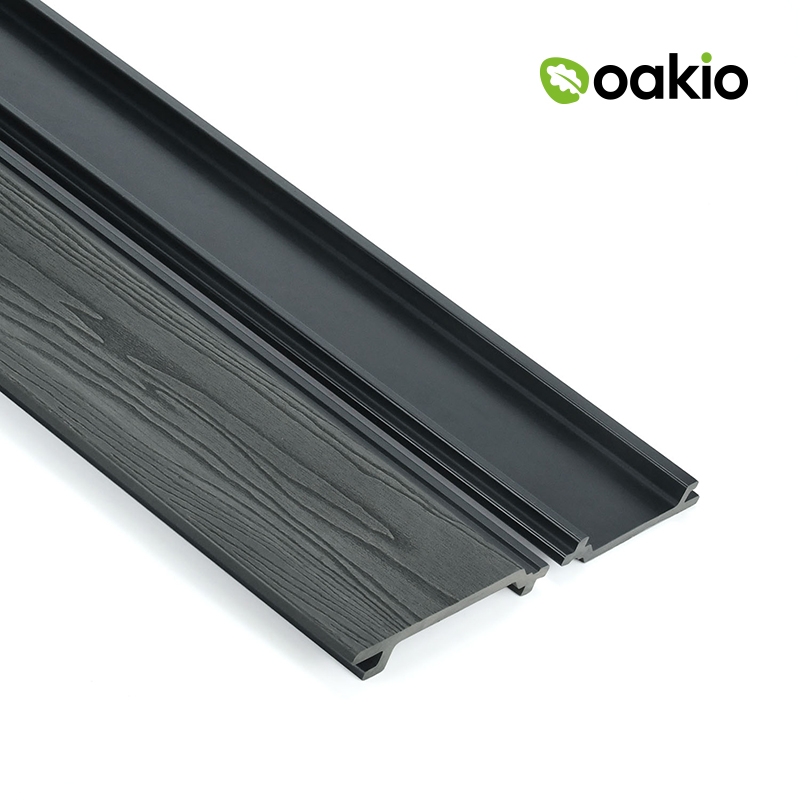

Oakio

External Cladding

With 95% of its boards made from reclaimed oak and other recycled products, Oakio external cladding is now available in the UK and its range is said to offer a low-or-no maintenance upgrade to timber and PVC cladding, as well as an alternative to hanging tiles.

The 3.6m length boards come in nine natural wood finishes including top selling grey in both dark and light shades. The company says there is no need to paint, stain or seal the boards and also that there is no risk of warping, splintering or fading. Reportedly easy to install, the cladding can be fixed both horizontally and vertically.

With products also suitable for applications such as decking and fencing, Katie Morley, MD at Ronjack, the UK’s sole supplier for Oakio, said: “Oakio is different from other products — the name comes from the primary component being reclaimed oak (and) it gives a more natural finish that homeowners want, and it is super hardwearing as well.”

To ensure nationwide delivery, Oakio is building a network of merchant partners to cover the whole of the UK.

For more details go to: www.oakiouk.com

James Jones & Sons

James Jones & Sons

Lockerbie Site

Already billed as the “showcase sawmill within the James Jones Group”, investment in a new visitor centre at the company’s facility in Lockerbie — constructed using extensive use of the firm’s own products — is intended to take matters to a new level. Claimed to be the largest single site sawmill complex in the UK and the most technically advanced, Lockerbie received a high number of visitors pre-pandemic — including small groups of customer visits, customer training courses, academic institutions and industry events.

The idea for the building is to provide significantly improved visitor facilities including a theatre-style briefing room and the opportunity to host training courses and industry meetings, which previously had to be conducted offsite. Moreover, the new building’s structure acts as a demonstration project, almost entirely erected from James Jones & Sons own products with an approach to minimising the use of steel and maximising timber.

In addition, the first floor is raised to give panoramic views across the timber yard and over the constant stream of unprocessed logs to the mill, which is directly below this space. Taking all the timber elements into account, the building fabric has almost 40 CO2TE within it.

Rob MacKenna, the site’s General Manager, said: “The striking design and innovative use of solid and engineered timber products are a great example of how timber can be used to deliver high quality office and meeting areas. The main meeting room has been positioned to achieve a stunning view across the Stevens Croft site, enabling visitors to view part of our operations from the comfort of this space.

“We look forward to a time when we can welcome back groups of visitors and host them in this fantastic new facility”.

Go to https://www.jamesjones.co.uk/about-us/our-locations/lockerbie for more information about the Lockerbie site.

Norbord

Norbord

SterlingOSB

Construction sites and vacant buildings are tempting places for thieves, trespassers, vandals, arsonists and children. A perimeter barrier, such as a site hoarding, is seen as the first and most important line of defence in securing a site and Norbord’s SterlingOSB Zero is described as an easy to use, consistent and great value solution for this purpose.

Security breaches have implications in terms of downtime, loss of revenue, increased insurance premiums and equipment replacement costs. They also do little for the PR effort when problems on a site become public.

According to the HSE, site boundaries must be defined physically, where necessary, by suitable fencing. The strength of SterlingOSB Zero makes it an appropriate choice for hoardings and, requiring minimal finishing, the product is available in a number of sheet sizes and thicknesses.

The boards are square-edged so butt together easily and cleanly, whilst nails can be driven as close as 8mm from the panel edge without causing splitting.

More information on Nordbord can be found via www.norbord.co.uk.

Makita

Makita

Carpentry-focused tools

Said to be ideal for the woodworking trades, Makita has expanded its 40VMax XGT range of high performance tools with the addition of a new Brushless Combi Drill, Brushless Brad Nailer and Brushless Circular saws.

The tools are all said to benefit from Makita’s “efficient and effective” brushless motor that minimises friction and energy wasted as heat which in turn maximises performance and run-times per battery charge for greater productivity.

As for the individual products, the 40VMax XGT Brushless Brad Nailer (FN001G) is compatible with 18Ga nails between 15 and 40 mm, has a magazine capacity of 100 and will drive up to 5,000 nails on a single 2.5Ah battery charge.

Two new 40VMax Circular Saws — RS001G and RS002G — feature 185mm and 260mm blades respectively. Both offer a comparable performance to the equivalent corded tool and feature Makita’s Automatic Torque Drive Technology (ADT) which automatically adjusts the cutting speed according to load conditions for optimum performance.

With a maximum speed of 6,400 rpm, the RS001G offers a maximum cutting depth of 65mm and a bevel angle of up to 53° whilst its stablemate is capable of delivering up to 4,000 rpm with a 95mm cutting depth and a bevel angle of up to 56°.

Alongside the new tools, three new job site radios have also been launched that are compatible with Makita’s 40VMax XGT, 18V LXT and 12VMax CXT batteries.

Use www.makitauk.com to discover more about the full 40VMax XGT range.