Joana Janusevicute, Territory Product Manager at Wavin, takes a look at how press-fit systems can be the perfect solution for busy plumbers and shares her thoughts on how merchants can sell more of them to their customers.

With the home improvement boom predicted to continue this year, there’s no sign of the workload slowing for tradespeople. Plumbers and installers are now facing a packed calendar in a very demanding market. However, by investing more in solutions which are designed to help ease the pressures, they’ll be able to get their jobs done much quicker, and protect their margins.

You’ve probably seen first-hand how attached trades can become to their tools and processes — with many taking an ‘if it aint broke, don’t fix it’ approach. Encouraging them to try something different, which will ultimately make their lives easier, can be tricky. So, that’s why being able to talk knowledgably to your customers about the advantages of newer products on the market can really add value.

Take press-fit products, for example. These are able to offer a host of benefits for plumbers, but might not be the first port of call for traditionalists. So, what should you be telling your time-poor customers about when it comes to press-fit products?

What is press-fit?

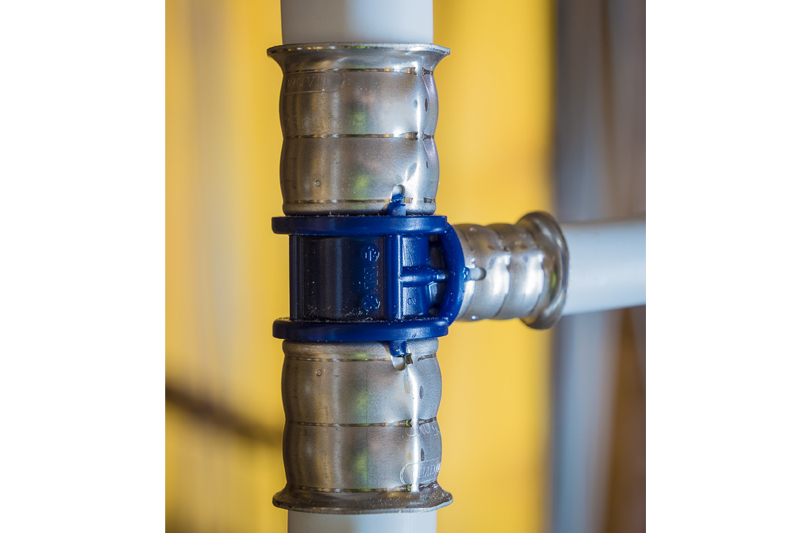

Unlike traditional plumbing systems which require hot works to connect pipes together, press-fit products don’t need heat. The installation process makes water-tight joints by inserting the pipe and fitting together, and then uses either a hand-operated or an electrical press-fitting tool to form the connection.

These innovative products were originally developed for commercial use, but they’re increasingly being used in domestic settings, because of the recognised benefits.

Efficient and safe

With tighter timeframes across the sector, on-site efficiency is becoming increasingly important. Your plumbing customers need to have access to solutions that can help cut their installation times, while still ensuring the end result will be fit and forget. This is where press-fit’s quicker installation processes come in — a benefit that has a ripple effect throughout an entire build, no matter if it’s a new housing development or a brand-new family bathroom.

Straightaway, the most time-consuming stage of traditional installation is removed with press-fit. So no more, threading, soldering or welding, and these products ensure your customers can create a completely secure fit in almost no time at all.

As no hot works are needed, this also means other people can be present whilst the installation is taking place. As the safety risks have been mitigated, with no flying sparks or solvent fumes, other tradespeople can continue with their work, helping to keep projects on track. As installation uses components assembled with dry joints, components can be pre-fabricated off-site before installation, which helps to cut down time even further.

Durable and flexible

Not only are press-fit systems more efficient, their flexibility also reduces the amount of fixings required to hold plumbing in place, allowing pipework to be easily installed within walls and other areas with restricted space like airing cupboards and under stairwells. This benefits installers, developers and end-users, as it means homes can be designed with aesthetics in mind — giving people as much useable space as possible, without compromising on the overall design or the performance of the plumbing system.

One solution that offers a more flexible fitout and durable end result, are the award-winning Tigris systems from Wavin. These press-fit pipes are compatible with virtually any existing systems, and are made using composite material which means that there’s no contact between metal and water when in use, which helps resist scale and corrosion.

Meanwhile, its high-performance Polyphenylsulfone (PPSU) fittings with fixed stainless-steel sleeves don’t expand or contract as much as traditional alternatives when the heating is on, minimising the stress placed on the system. Both of these features help to reduce maintenance requirements, and ensure that systems will have a long and productive life, no matter where they’re installed.

By talking to your customers about the benefits of press-fit products, you can offer them advice and solutions that take the pressure off at a time when they’re under more than ever.

Click the link to find out more about Wavin’s Tigris press-fit system.

A version of this article appeared in the April edition of PBM. Click the link to read the full digital issue.